@cnhoff Lol, snap!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tactile Immersion - General Discussion - Hardware & Software

- Thread starter Mr Latte

- Start date

https://www.amazon.co.uk/dp/B08KJ8MLXYneoprene washers are hard to find in the UK

@cnhoff and @metalnwood thanks for the example photos, these are very helpful. I think I will:

- Drop my P1-X pedal tray down as low as it will go (I've got 2 "slots" on the side profiles that I can slide down)

- Mount the isolators on the cross sections like you have

- Have 1 isolator mounting plate fabricated (might require me to use a smaller piece of profile on one of the cross sections, so the transducers fit between them)

- Have 2 pedals mounting trays (one for racing and one for flight) fabricated that bolt down onto the isolator mounting plate

Last edited:

Sounds good, the 2 plates one for pedal and one for rudder is ideal.@cnhoff and @metalnwood thanks for the example photos, these are very helpful. I think I will:

Seems like this will be my simplest and most effective solution.

- Drop my P1-X pedal tray down as low as it will go (I've got 2 "slots" on the side profiles that I can slide down)

- Mount the isolators on the cross sections like you have

- Have 1 isolator mounting plate fabricated (might require me to use a smaller piece of profile on one of the cross sections, so the transducers fit between them)

- Have 2 pedals mounting trays (one for racing and one for flight) fabricated that bolt down onto the isolator mounting plate

Also, no reason why you cannot mount the p1 pedal tray upside down so you can then go a lot lower with its side mounts on the top. Just means that if your new pedal tray has to fit between them it has to be less than 480mm wide instead of 500mm

@Callsign BH sim labs makes a pedal plate with pre-done holes for mounting pedals onto them... it's a hefty chunk of aluminum, It's what I am using on top my p1-x pedal tray.@cnhoff and @metalnwood thanks for the example photos, these are very helpful. I think I will:

Seems like this will be my simplest and most effective solution.

- Drop my P1-X pedal tray down as low as it will go (I've got 2 "slots" on the side profiles that I can slide down)

- Mount the isolators on the cross sections like you have

- Have 1 isolator mounting plate fabricated (might require me to use a smaller piece of profile on one of the cross sections, so the transducers fit between them)

- Have 2 pedals mounting trays (one for racing and one for flight) fabricated that bolt down onto the isolator mounting plate

On a side note, my two behringer nx1000d are apparently on backorder from sweetwater until may.

Last edited:

D

Deleted member 197115

-

Deleted member 197115

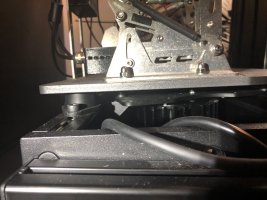

That plate goes on the top of pedal deck and as you can see there is not enough room under to mount transducers.@Callsign BH sim labs makes a pedal plate with pre-done holes for mounting pedals onto them... it's a hefty chunk of aluminum, It's what I am using on top my p1-x pedal tray.

On a side note, my two behringer nx1000d are apparently on backorder from sweetwater until may.

If he drops that pedal deck all the way down and then depending how big of spaces he puts inThat plate goes on the top of pedal deck and as you can see there is not enough room under to mount transducers.

View attachment 525159

Yes, as it is, clearly there is not enough room to just slide them under. That would be too easy. However, I think that is why he had said in step 3. "(might require me to use a smaller piece of profile on one of the cross sections, so the transducers fit between them)". Also, another way would be to elevate the isolators to have increased height. I think that is the reason for his step 1 in dropping down the pedal deck as much as he can, to counter the increased height. I would however guess that buying an already fabricated plate will be considerably cheaper than trying to have one or two custom made.That plate goes on the top of pedal deck and as you can see there is not enough room under to mount transducers.

View attachment 525159

Last edited:

Ah, I didnt realise that the new p1's have a large piece of profile there.

@Callsign BH what you can do there, I did at one point is to not replace it but pretend its 80x40 not 160x40 and just have half of it sticking out behind past the side mounts. Its only aesthetic and doubt it will be noticed much anyhow..

@Callsign BH what you can do there, I did at one point is to not replace it but pretend its 80x40 not 160x40 and just have half of it sticking out behind past the side mounts. Its only aesthetic and doubt it will be noticed much anyhow..

Last edited:

D

Deleted member 197115

-

Deleted member 197115

Two 40x40 pieces of profile cut to size will do, not sure if will be that beneficial to the rigidity of the pedal deck though.might require me to use a smaller piece of profile on one of the cross sections, so the transducers fit between them

Last edited by a moderator:

I would not use 40x40 personally as I feel that would be too much flex. I am thinking smallest I would go is two 40x80's or if you wanted to get back the rigidity you could replace that 40x160 with a 80x80 and would probably give similar strength. I think you would be able to stick at least a BKA in between those. Unsure about a LFE though.Two 40x40 pieces of profile cut to size will do, not sure if will be that beneficial to the rigidity of the pedal deck though.

Edit: You would also need to drill a countersunk hole into those side plates for the new crossmembers to screw into the plate, but that is easy enough just measure 40mm over from thecenter of front hole, mark, punch, drill press, countersink, done. Like where is marked in red.

Attachments

Last edited:

D

Deleted member 197115

-

Deleted member 197115

I think the optimal fix it just to get rid of these crossmembers altogether and install cut to size metal plate on corner brackets bolted directly to pedal side mounts with isolators in between..

How much pedals on isolators move under pressure during hard braking? From when I had transducers on pedal plate (without isolators) the effect was very underwhelming, with only contact point being racing shoes thick rubber heel absorbing everything, I don't see it being that great even with isolation.

How much pedals on isolators move under pressure during hard braking? From when I had transducers on pedal plate (without isolators) the effect was very underwhelming, with only contact point being racing shoes thick rubber heel absorbing everything, I don't see it being that great even with isolation.

Last edited by a moderator:

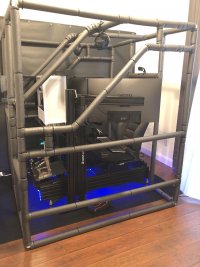

hey guys...perfect match for my question the above few posts... so finally my 2 x NX3000D arrived. i can now mount my 2 x TST429 + 2BK LFE on the rig. I will remove the 1 aura I had under the pedal tray and add it to the 3 I have on the seat.

as I also use a P1X with the pedal tray it was easier for me to just turn the 2 horizontal profiles of the pedal tray vertically until my custom cut 40x80 arrive. the pedal tray is currently seating on four of these https://www.mcmaster.com/catalog/127/1570 and they seem fine. my first question would be if it would make sense to drill holes on my 8mm steel pedal tray and attach the first set of TST & BK there or need to leave some gap

the 2nd question is in line with the above...would it make better sense to have a plate under the seat to add the 2nd set of TST & BK or just drill hole at the bottom of seat and also attach these there..i already have 3 and 1 extra today auras on the seat ... havent mount a decent way to isolate the seat properly, but getting there

last but not least...is there a simhub profile for the TST429 & BK LFE available?

just a couple of pictures for reference

rig is still work in progress...many things still to do overall

as I also use a P1X with the pedal tray it was easier for me to just turn the 2 horizontal profiles of the pedal tray vertically until my custom cut 40x80 arrive. the pedal tray is currently seating on four of these https://www.mcmaster.com/catalog/127/1570 and they seem fine. my first question would be if it would make sense to drill holes on my 8mm steel pedal tray and attach the first set of TST & BK there or need to leave some gap

the 2nd question is in line with the above...would it make better sense to have a plate under the seat to add the 2nd set of TST & BK or just drill hole at the bottom of seat and also attach these there..i already have 3 and 1 extra today auras on the seat ... havent mount a decent way to isolate the seat properly, but getting there

last but not least...is there a simhub profile for the TST429 & BK LFE available?

just a couple of pictures for reference

rig is still work in progress...many things still to do overall

Attachments

Last edited:

I doubt very much that simlab have gone for such large profiles to minimise flex on the pedal plate. Its much more likely that they have done this to give you a large area for mounting options.

Bear in mind that the forces on these are not happening in the middle part of the span of the profile they are happening near the edges where things will be mounted. The fact that they span the width is more conincidental.

Bear in mind that the forces on these are not happening in the middle part of the span of the profile they are happening near the edges where things will be mounted. The fact that they span the width is more conincidental.

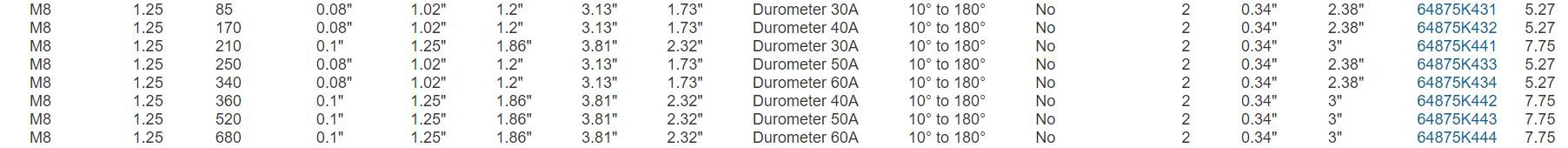

Oh, I like these isolators a lot. Can you tell me which durametor hardness you went with and why? Seems like if you go too hard, it would reduce isolation by more vibrations going to the frame. However, if you went to soft it would introduce flex when braking. Seems like it would be one of these from near the bottom of the page.hey guys...perfect match for my question the above few posts... so finally my 2 x NX3000D arrived. i can now mount my 2 x TST429 + 2BK LFE on the rig. I will remove the 1 aura I had under the pedal tray and add it to the 3 I have on the seat.

as I also use a P1X with the pedal tray it was easier for me to just turn the 2 horizontal profiles of the pedal tray vertically until my custom cut 40x80 arrive. the pedal tray is currently seating on four of these https://www.mcmaster.com/catalog/127/1570 and they seem fine. my first question would be if it would make sense to drill holes on my 8mm steel pedal tray and attach the first set of TST & BK there or need to leave some gap

the 2nd question is in line with the above...would it make better sense to have a plate under the seat to add the 2nd set of TST & BK or just drill hole at the bottom of seat and also attach these there..i already have 3 and 1 extra today auras on the seat ... havent mount a decent way to isolate the seat properly, but getting there

last but not least...is there a simhub profile for the TST429 & BK LFE available?

just a couple of pictures for reference

rig is still work in progress...many things still to do overall

Attachments

I went with 60A. From experience with my race car it wouldnt make a big difference between 50-60. I wanted less flex and some isolation. The different with and without them on tactile effect is apparent so I am happy. I am working on a different arrangement to isolate the seat which is slightly more complicated but I ll get there in a week or so.Oh, I like these isolators a lot. Can you tell me which durametor hardness you went with and why? Seems like if you go too hard, it would reduce isolation by more vibrations going to the frame. However, if you went to soft it would introduce flex when braking. Seems like it would be one of these from near the bottom of the page.

D

Deleted member 197115

-

Deleted member 197115

Useful hardness reference https://mykin.com/rubber-hardness-chart

So which particular model did you get, your link points to the whole page of isolators?

So which particular model did you get, your link points to the whole page of isolators?

Last edited by a moderator:

I would say based that we want M8 threads there are only a few on the list. Since you would not want one that was too much wider than the 40mm width of our frame that narrows it down further. Since he just said he went with 60A. I am going to guess that he went with the 64875K434. However, that is just a guess. link belowUseful hardness reference https://mykin.com/rubber-hardness-chart

So which particular model did you get, your link points to the whole page of isolators?

Edit: That being said, I really do wonder if the 50A or even the 40A would be more suitable for our needs. Max weight for 50A is 250lbs each and the 40A is 170lbs each. Since we are using 4 that is a lot of strength already. I would think by slightly reducing the hardness to a more suitable weight range it would further reduce vibrations transmitting to the frame.

60A:

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

50A:

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

40A:

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Last edited:

@paladin21I went with 60A. From experience with my race car it wouldnt make a big difference between 50-60. I wanted less flex and some isolation. The different with and without them on tactile effect is apparent so I am happy. I am working on a different arrangement to isolate the seat which is slightly more complicated but I ll get there in a week or so.

Is there a reason that the same isolators couldn't be used for the seat in the same way as the pedal deck? Seems to me, I could just use these in the same manor that @Andrew_WOT showed his mounted previously. (between the seat slider and the seat)

Last edited:

@paladin21

Is there a reason that the same isolators couldn't be used for the seat in the same way as the pedal deck? Seems to me, I could just use these in the same manor that @Andrew_WOT showed his mounted previously. (between the seat slider and the seat)

I got 8 of them at the beginning and worked great with my previous seat (was a C6Z06 stock seat). when i added the fiberglass seat, as I wouldnt want to drill holes to a very nice seat, and added the extra seat rails there was some Squicking from the rail rubbing on the rubber. The Z06 seats have integrated rails as part of the seat and the mount are extended further back and rear (zoom in the picture and see the seat attachment points). Dont like things squicking when the motion platform is working so i removed them from under the rails.

I am thinking to use something like this https://8020.net/40-4375-black.html and mount the 40x40 profiles on the horizontal surface of the brackets and add vibration dampeners on the vertical sides where the bracket will be attached to the P1X. that way I will have both damping and no squicking noises ...hopefully...havent tried it yet

the thing is that now with the additional parts that arrived the seat will have 4 x auras + a TST429 + a BK LFE...should be interesting (cage goes back once i am done with tactile. Made a carbon fibre look roof/sides as well)

Attachments

Last edited:

Latest News

-

Macau Grand Prix in Sim Racing: Deserving of More?This weekend is the Macau Grand Prix and whilst a shadow of its former self, this tight street...

- Angus Martin

- Updated:

- 3 min read

-

How One Announcement Quadrupled Forza Horizon 4's Player BaseIt is exactly one month until Forza Horizon 4 will no longer be available to purchase online...

- Angus Martin

- Updated:

- 2 min read

-

Assetto Corsa EVO New Car Configurator In The PipelineAfter this year's sim Racing Expo, the excitement around Assetto Corsa EVO has continued to...

- Connor Minniss

- Updated:

- 2 min read

-

Steering Wheel Showdown: Which Wheel Would You Like A Sim Racing Version Of?Sim racers have plenty of choice when it comes to hardware. There are a number of cool steering...

- Yannik Haustein

- Updated:

- 2 min read

-

Gran Turismo 7: Yamauchi Teases New Cars For Update 1.53It is that time again when Gran Turismo series producer Kazunori Yamauchi teases us with an...

- Luca Munro

- Updated:

- 5 min read

-

Automobilista 2: Incoming DLC Will Have Free Trial PeriodWith the big v1.6 update, plenty of new content is coming to Automobilista 2. Players who are on...

- Yannik Haustein

- Updated:

- 2 min read

-

Le Mans Ultimate Online Subscriptions Expected To Arrive In December 2024Ahead of the expected December update to Le Mans Ultimate, Motorsport Games reported its Q3...

- Yannik Haustein

- Updated:

- 2 min read