Looks really incredible man, loved the video. Good to hear the rig is fully coming together for you with the hardware performance you were looking for. Enjoy it!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile Driving/Flying Cockpit with Motion and Tactile ( Build )

RCHeliguy

Premium

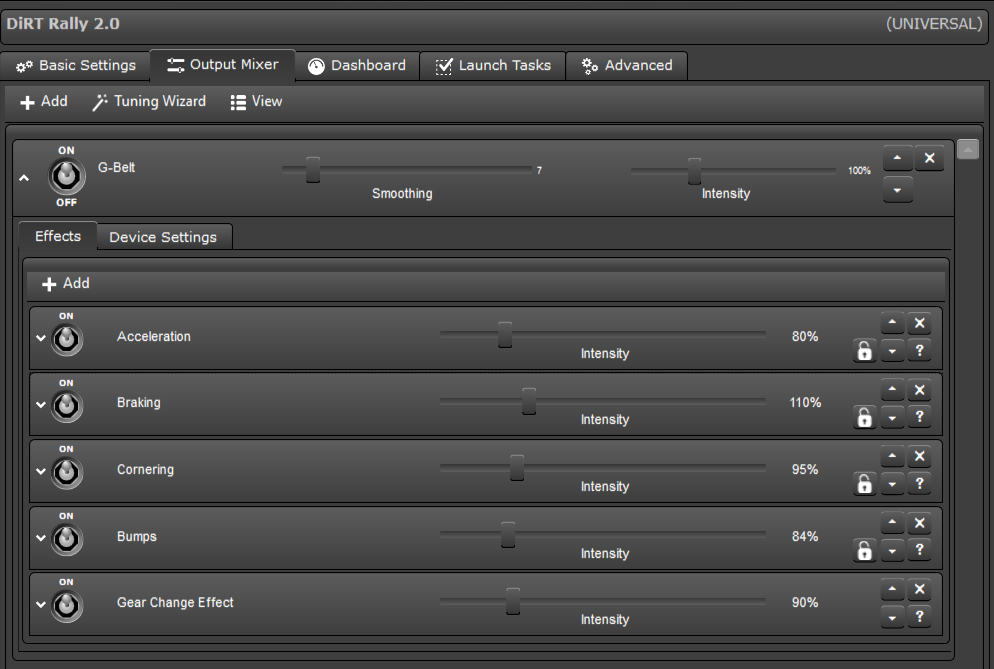

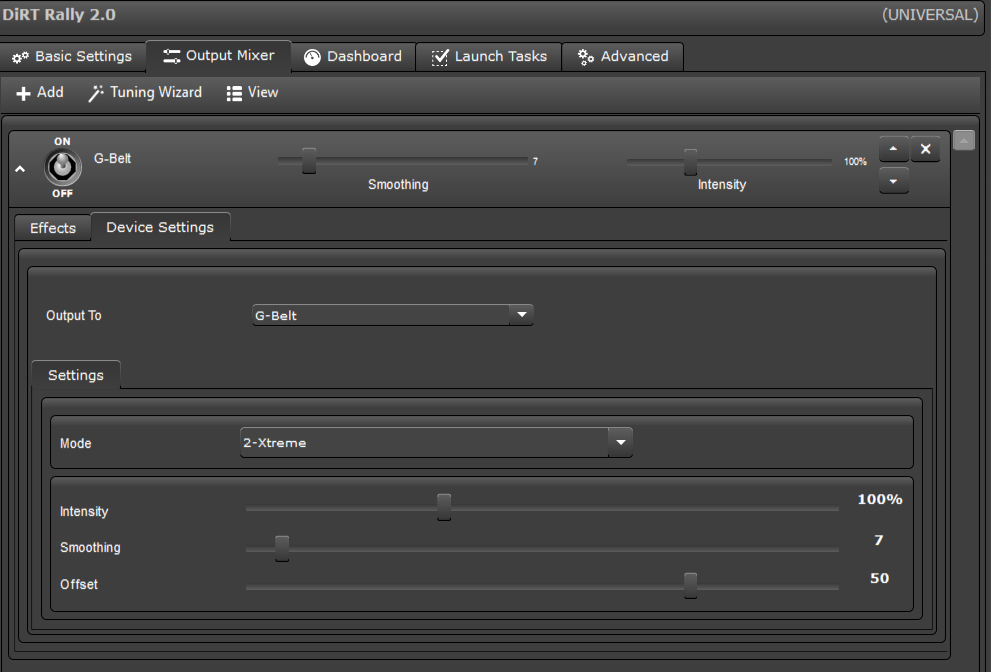

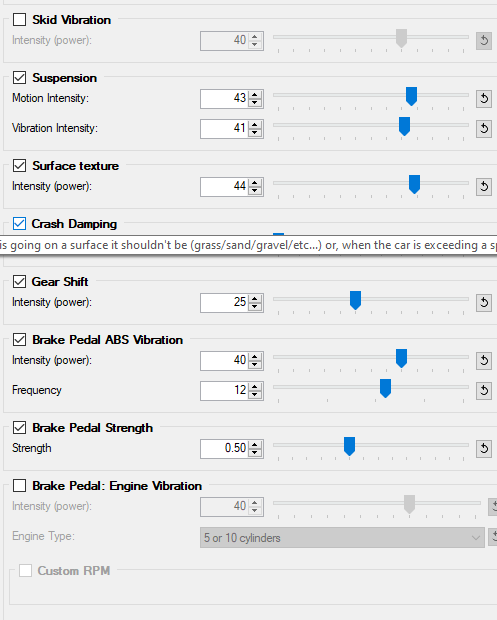

My G-Belt Dirt Rally settings.

Smoothing set to 7 is just enough to keep the bumps effect from being "too busy" and the bump effect really works well to reinforce the D-Box motion by effectively working in the opposite direction.

Since the cars slide easily in most stages, I have the full brake setting set to 1G and the cornering set to 1.5G. Bumps are at 2G.

For the gear shift effect I'm running +/- about 28.

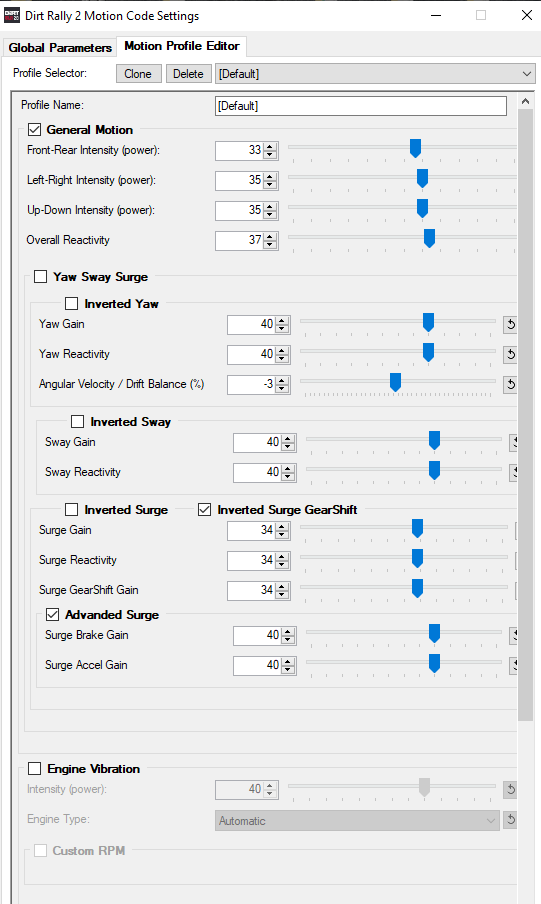

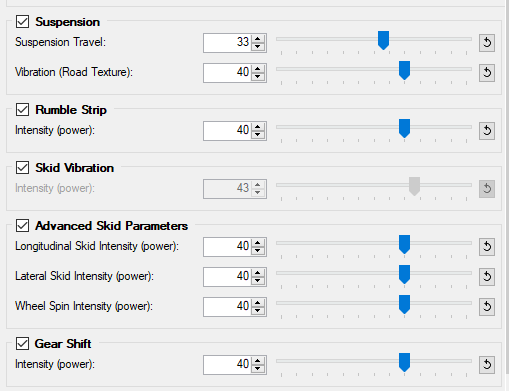

D-Box settings

For the engine, I keep going back to Rodney's V1 engine. However I believe this is a 10.7 iteration.

SimHub

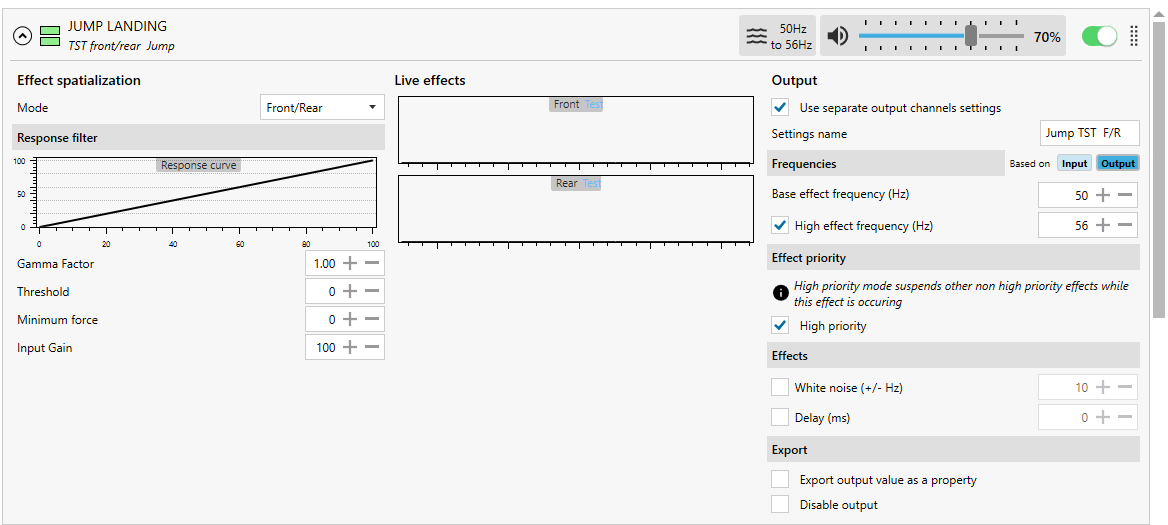

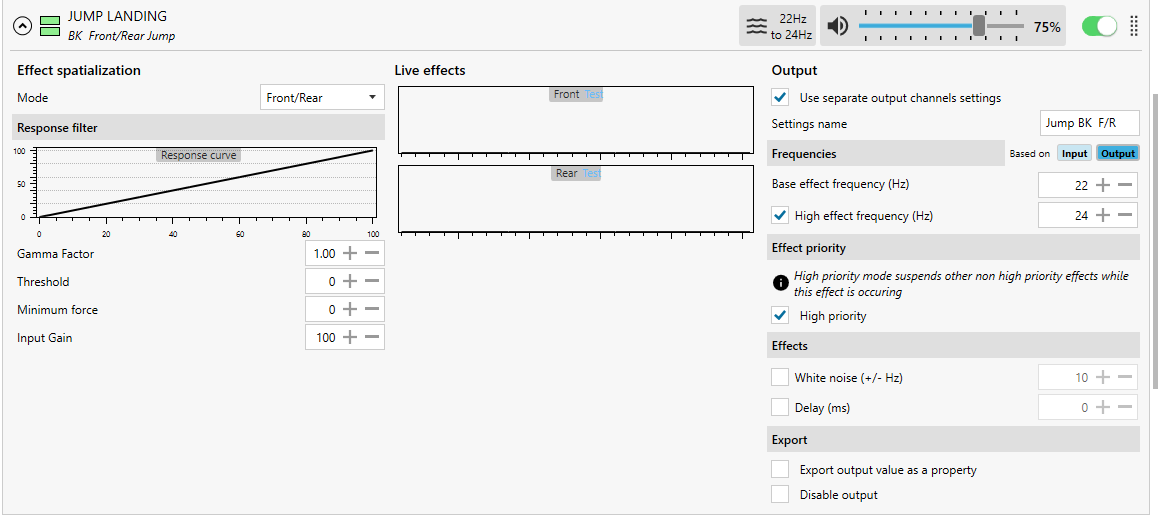

The Jump landing effect seriously helps the complete the feeling when landing a jump with the D-Box which just needs a little help to make this feel right. I created a TST and BK effect for these. They work together to make this feel very good. It adds just a little concussive force that makes all the difference.

From what I can tell, neither the D-Box wheel slide or the SimHub Wheel Slip effects are triggered on gravel and they only appear on asphalt and ice. I'll revisit this later.

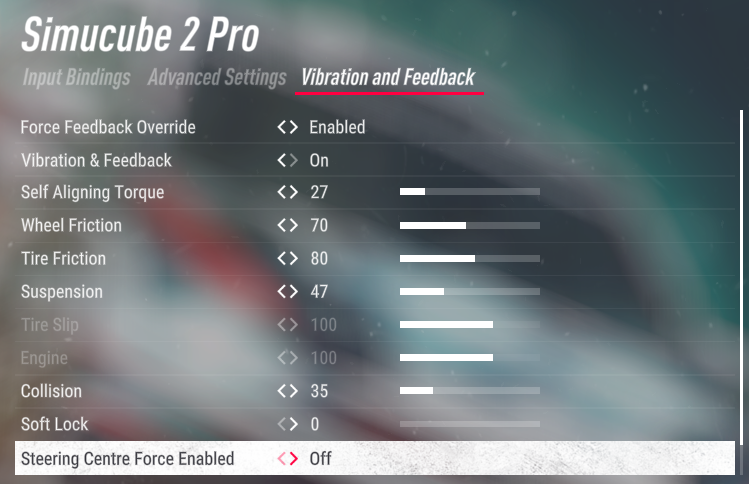

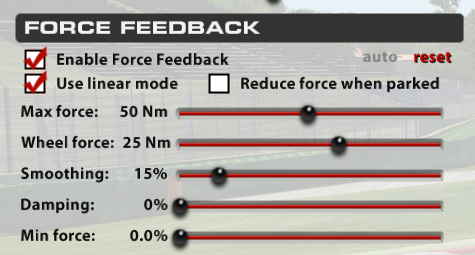

For completeness my Dirt Rally FFB settings.

Smoothing set to 7 is just enough to keep the bumps effect from being "too busy" and the bump effect really works well to reinforce the D-Box motion by effectively working in the opposite direction.

Since the cars slide easily in most stages, I have the full brake setting set to 1G and the cornering set to 1.5G. Bumps are at 2G.

For the gear shift effect I'm running +/- about 28.

D-Box settings

For the engine, I keep going back to Rodney's V1 engine. However I believe this is a 10.7 iteration.

SimHub

The Jump landing effect seriously helps the complete the feeling when landing a jump with the D-Box which just needs a little help to make this feel right. I created a TST and BK effect for these. They work together to make this feel very good. It adds just a little concussive force that makes all the difference.

From what I can tell, neither the D-Box wheel slide or the SimHub Wheel Slip effects are triggered on gravel and they only appear on asphalt and ice. I'll revisit this later.

For completeness my Dirt Rally FFB settings.

Last edited:

RCHeliguy

Premium

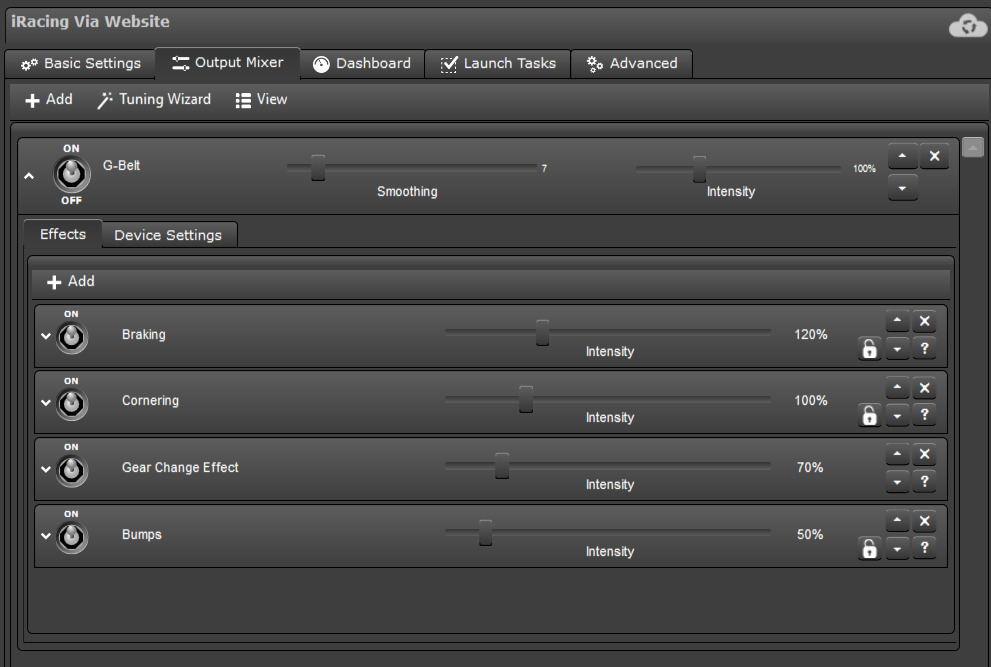

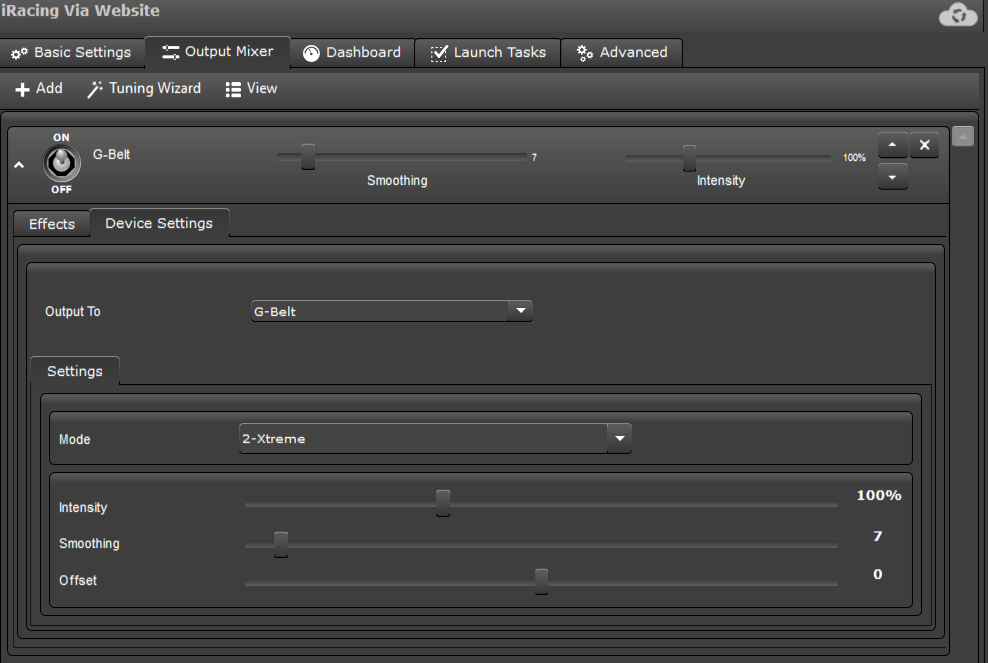

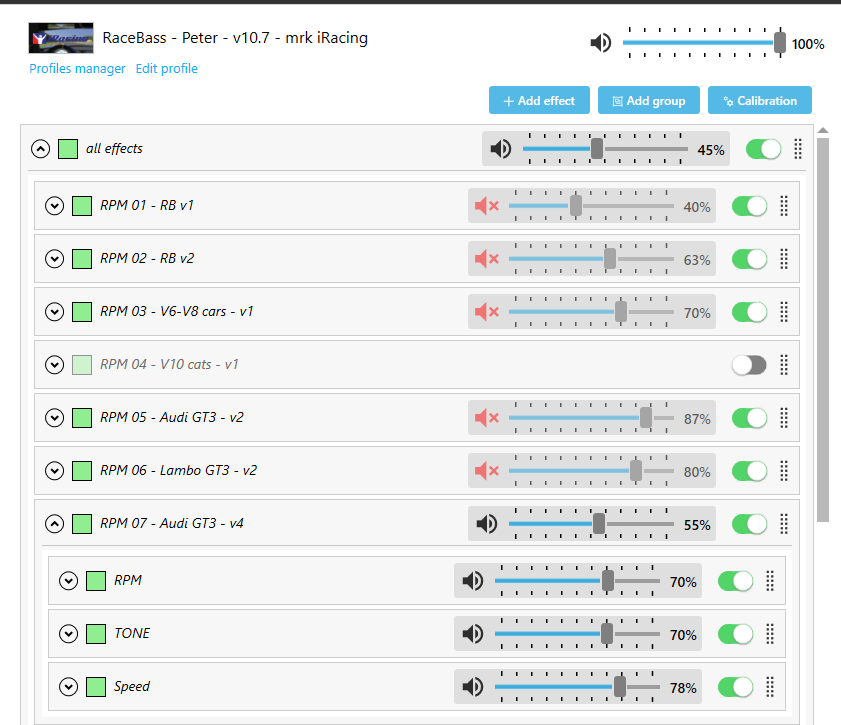

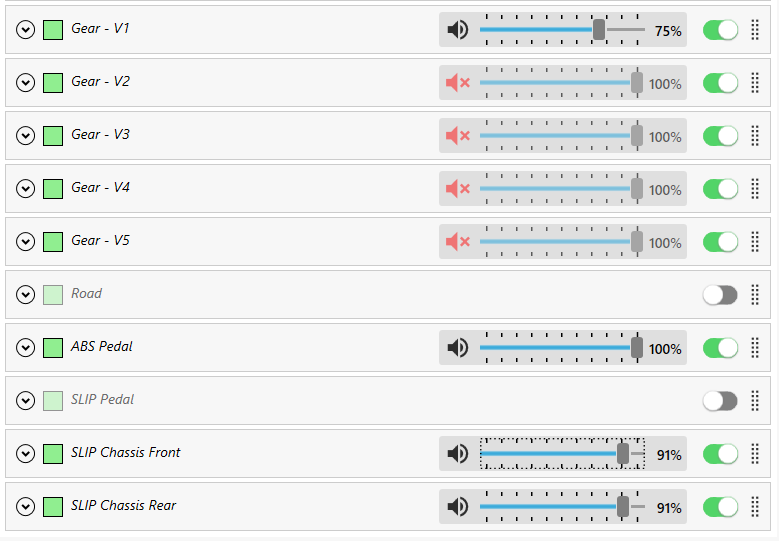

Now for iRacing

I recently added Bumps to iRacing as well. Once again with the smoothing up to 7 it's no longer too busy for my taste. I may need to adjust the gear change effect per shift amounts based on a recent discussion.

For iRacing and the Ferrari 488 EVO I like the Audi GT3 v4 engine with the speed effect turned up a bit so you can feel the speed increasing in the straights above 100 mph.

The slip Chassis works well and feels better than the D-Box slip effect that has a wonky bumpy feel to it.

The D-Box ABS feel is actually pretty good and I sometimes turn the SimHub ABS effect off. I also tend to adjust the strength of the Slip Chassis tactile effects depending on the track and car.

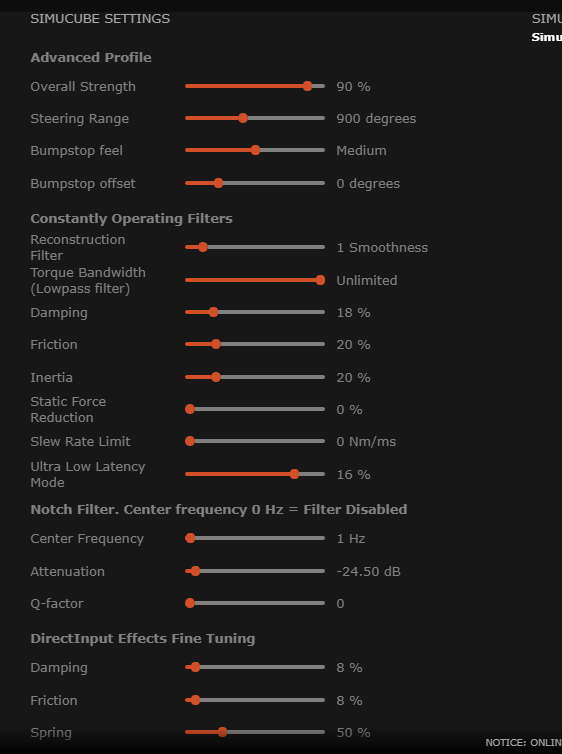

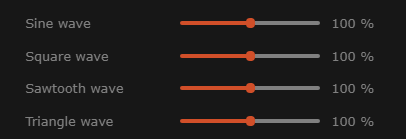

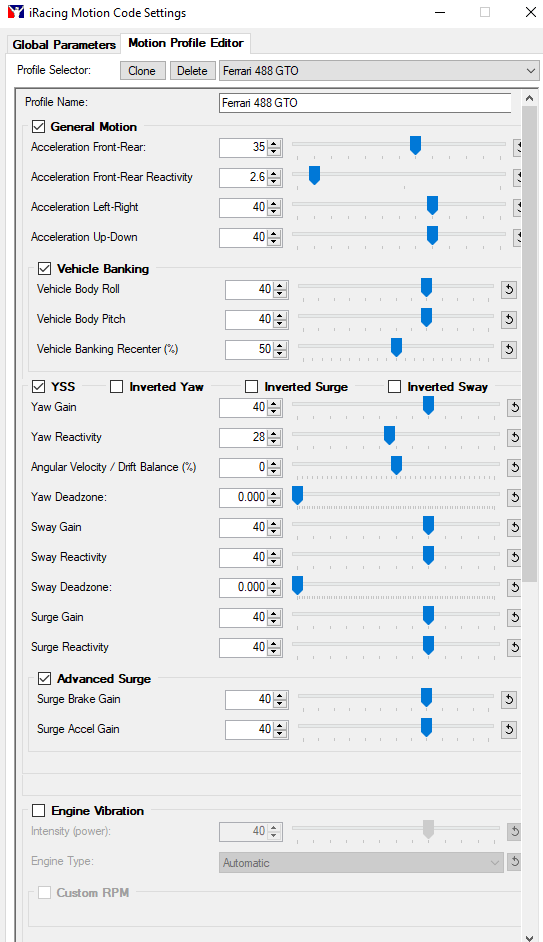

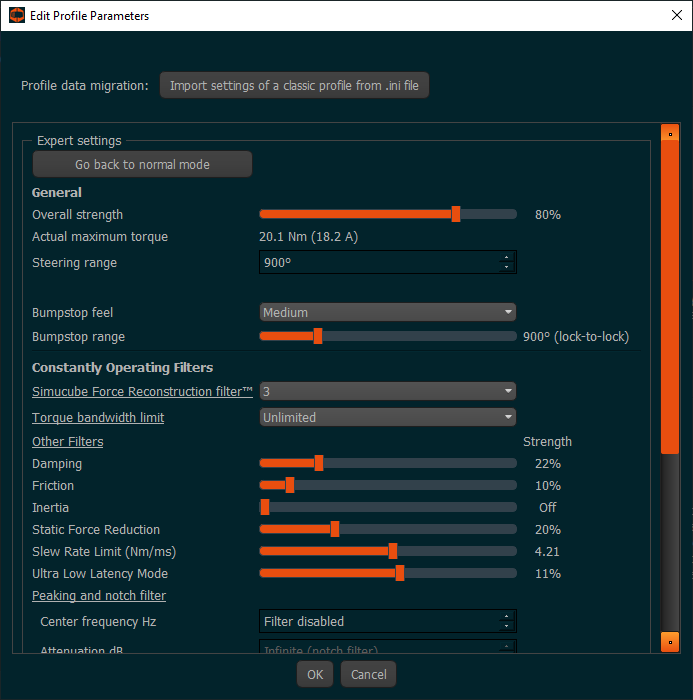

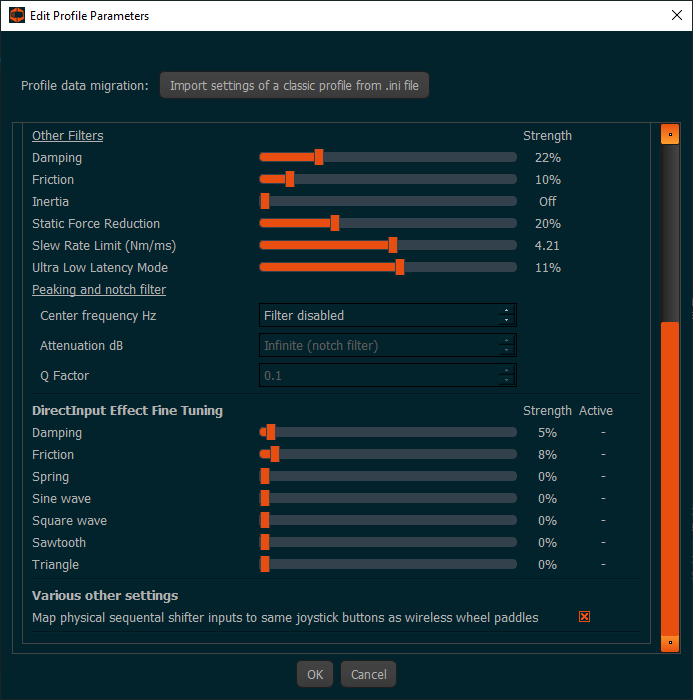

Edit: 12/7/2022 Added the SC2 Profile since it was requested:

I recently added Bumps to iRacing as well. Once again with the smoothing up to 7 it's no longer too busy for my taste. I may need to adjust the gear change effect per shift amounts based on a recent discussion.

For iRacing and the Ferrari 488 EVO I like the Audi GT3 v4 engine with the speed effect turned up a bit so you can feel the speed increasing in the straights above 100 mph.

The slip Chassis works well and feels better than the D-Box slip effect that has a wonky bumpy feel to it.

The D-Box ABS feel is actually pretty good and I sometimes turn the SimHub ABS effect off. I also tend to adjust the strength of the Slip Chassis tactile effects depending on the track and car.

Edit: 12/7/2022 Added the SC2 Profile since it was requested:

Last edited:

RCHeliguy

Premium

In the experiment category, I ordered a pair of flight shoes. I don't want to use my driving shoes with my Slaw pedals. I'm concerned the knurled posts will abrade the thin soles.

These are similar to driving shoes in that they are supposed to allow you to feel the pedals although they are made for walking and have a thicker sole. The main difference is that they have nylon tabs on the heel that allow the shoes to slide on the foot plate.

I'm not sure if they will work well with my Slaw pedals. I do wonder if there may be any crossover for driving with people who would like their heels to slide.

They are normally $129.99, but I guess this color wasn't popular so they put it on sale for $39.99.

These are similar to driving shoes in that they are supposed to allow you to feel the pedals although they are made for walking and have a thicker sole. The main difference is that they have nylon tabs on the heel that allow the shoes to slide on the foot plate.

I'm not sure if they will work well with my Slaw pedals. I do wonder if there may be any crossover for driving with people who would like their heels to slide.

They are normally $129.99, but I guess this color wasn't popular so they put it on sale for $39.99.

Last edited:

RCHeliguy

Premium

I'm finally scripting my best attempt at a tactile video. However it's going to take some time to do right. Most of my videos are 1 take hack jobs. This will need to be done carefully since I don't want to be confusing, and I want to make sure that what I create is actually helpful to someone trying to figure things out.

In the meantime my wife got me an early Christmas present to help with my unfortunate next project.

This is 13 years ago.

This was taken today. In a few places an otherwise sound deck is rotting.

This board looks most great between the posts on the left, but the board wasn't tied into the header on the right, so it moved a bit and all those little screw holes got bigger and bigger and let water in.

It's mostly 3 boards on the outer edge, but I will be taking additional preventative measures.

I've removed all the synthetic cover boards that I need to remove.

Normally I would just hire some professionals do this kind of work, but they are all booked 6-8 months out and aren't interested unless I give them permission to tear the entire deck down and the cost of the deck is now about 2.5-3 X what I paid when it was first put up. It's both the hourly rate and the cost of lumber and synthetic boards.

Basically I'm looking at some tedious work to be careful with the synthetics removing plugs and screws and Carefully fitting the boards that I can no longer get a matching color for.

In the meantime my wife got me an early Christmas present to help with my unfortunate next project.

This is 13 years ago.

This was taken today. In a few places an otherwise sound deck is rotting.

This board looks most great between the posts on the left, but the board wasn't tied into the header on the right, so it moved a bit and all those little screw holes got bigger and bigger and let water in.

It's mostly 3 boards on the outer edge, but I will be taking additional preventative measures.

I've removed all the synthetic cover boards that I need to remove.

Normally I would just hire some professionals do this kind of work, but they are all booked 6-8 months out and aren't interested unless I give them permission to tear the entire deck down and the cost of the deck is now about 2.5-3 X what I paid when it was first put up. It's both the hourly rate and the cost of lumber and synthetic boards.

Basically I'm looking at some tedious work to be careful with the synthetics removing plugs and screws and Carefully fitting the boards that I can no longer get a matching color for.

RCHeliguy

Premium

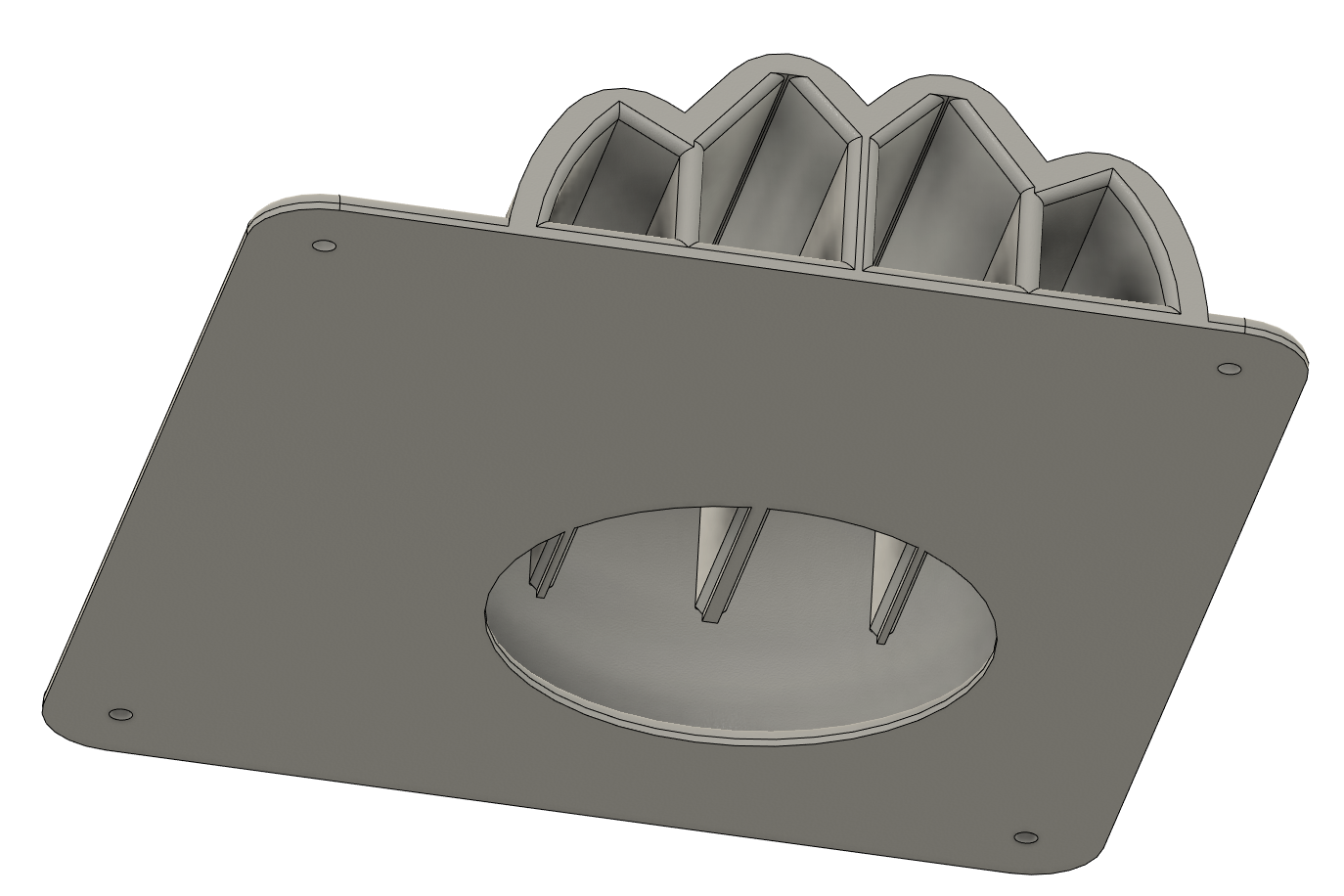

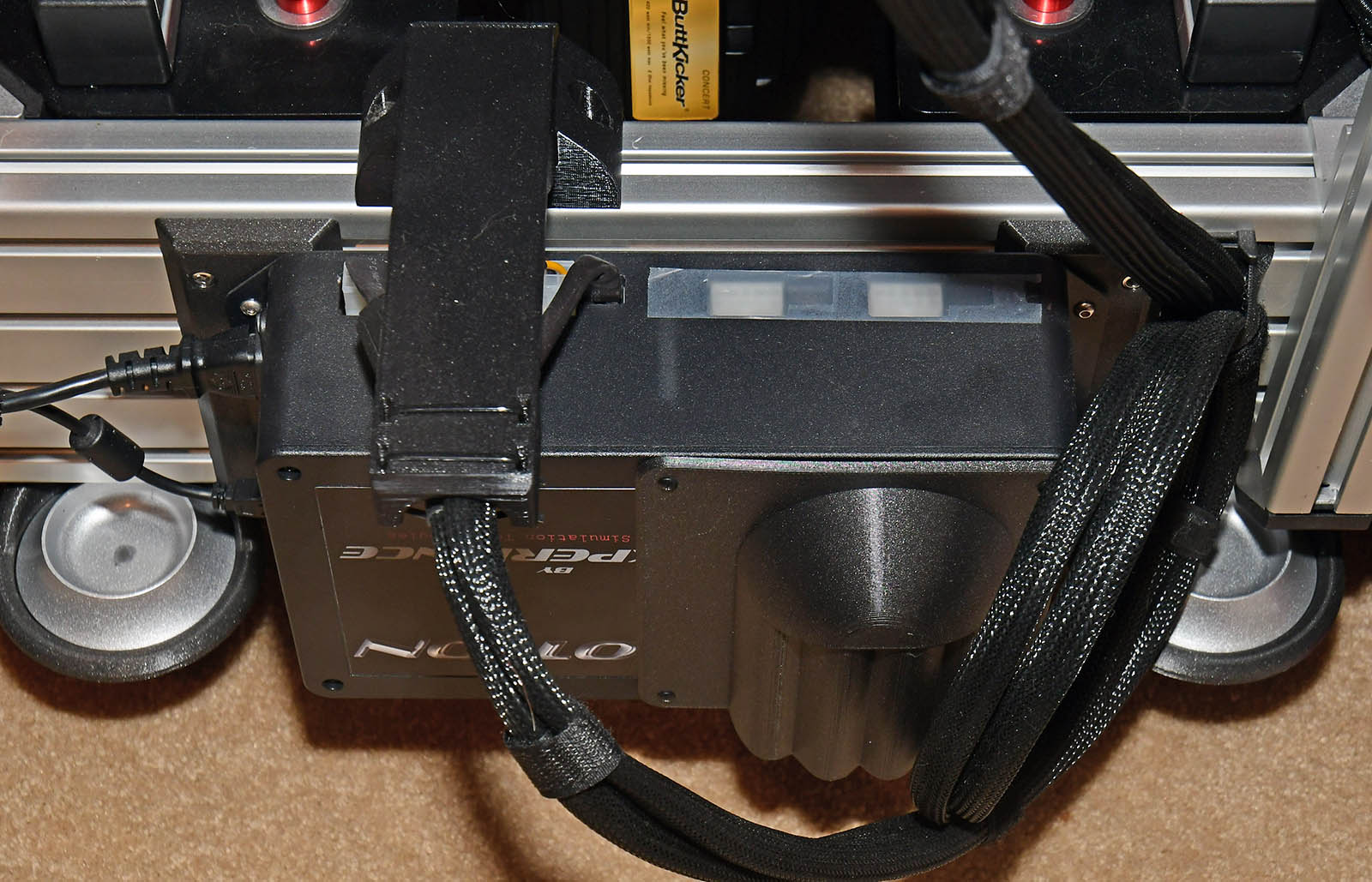

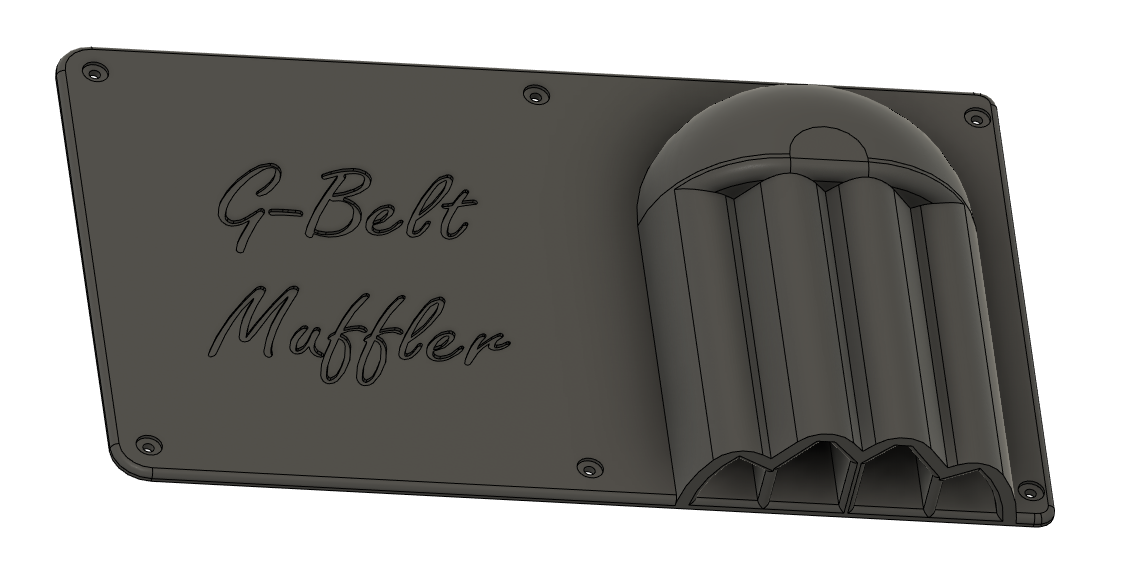

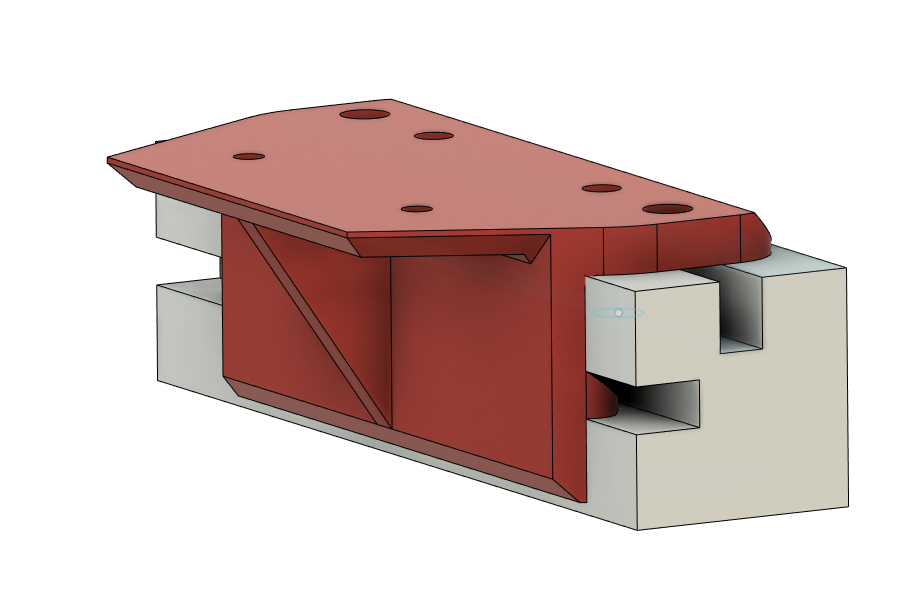

Yesterday I was in a conversation with a number of people who were buying G-Belts. One guy removed the decal off the actuator control box. So it got me thinking of making a replacement cover for the G-Belt actuator control box purely for aesthetics.

Then I changed directions and thought why not create something that has an impact on the fan sound of the Meanwell power supply. So I changed the design of the shroud to something with baffles that would direct the air in from the bottom. So it is more like a muffler.

To my ears it drops the volume and lowers the pitch to something more pleasant. According to my NLE it is about -35dB without the shroud and -41dB with the shroud. I'm sure the design could be improved.

I haven't quite figured out what aesthetic I want to go for.

This is a potential full coverage plate that could just go over the existing cover using the same screws.

www.thingiverse.com

www.thingiverse.com

Then I changed directions and thought why not create something that has an impact on the fan sound of the Meanwell power supply. So I changed the design of the shroud to something with baffles that would direct the air in from the bottom. So it is more like a muffler.

To my ears it drops the volume and lowers the pitch to something more pleasant. According to my NLE it is about -35dB without the shroud and -41dB with the shroud. I'm sure the design could be improved.

I haven't quite figured out what aesthetic I want to go for.

This is a potential full coverage plate that could just go over the existing cover using the same screws.

G-Belt Muffler by RCHeliGuy

This is a muffler that reduces the sound from the G-Belt.It uses the existing 6 screws mounts over the top of the existing plate.This video allows you to hear with and without the muffler.The small print uses only 4 bolts.The large print barely fits inside the print volume of a Prusa i3Also...

Last edited:

RCHeliguy

Premium

That's the intake. It exhausts through slits in the sides.Does it pump out much heat? If so perhaps it could be more efficient if the exhaust was rotated 90 degrees such that warm air could freely flow over and up. .

RCHeliguy

Premium

This was a very successful experiment!

First of all notice how incredibly smooth and quiet the Slaw pedals are

These shoes make them even smoother!

FWIW I tried them out on my driving pedals and no bueno. The soles are a little too thick and the sliding nylon just did not feel right for me.

First of all notice how incredibly smooth and quiet the Slaw pedals are

These shoes make them even smoother!

FWIW I tried them out on my driving pedals and no bueno. The soles are a little too thick and the sliding nylon just did not feel right for me.

RCHeliguy

Premium

I could see this becoming addictive.

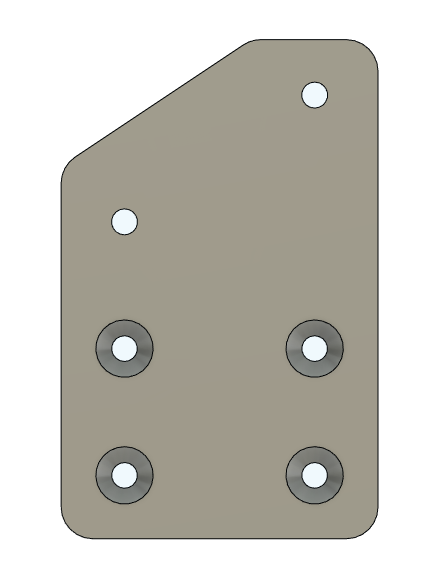

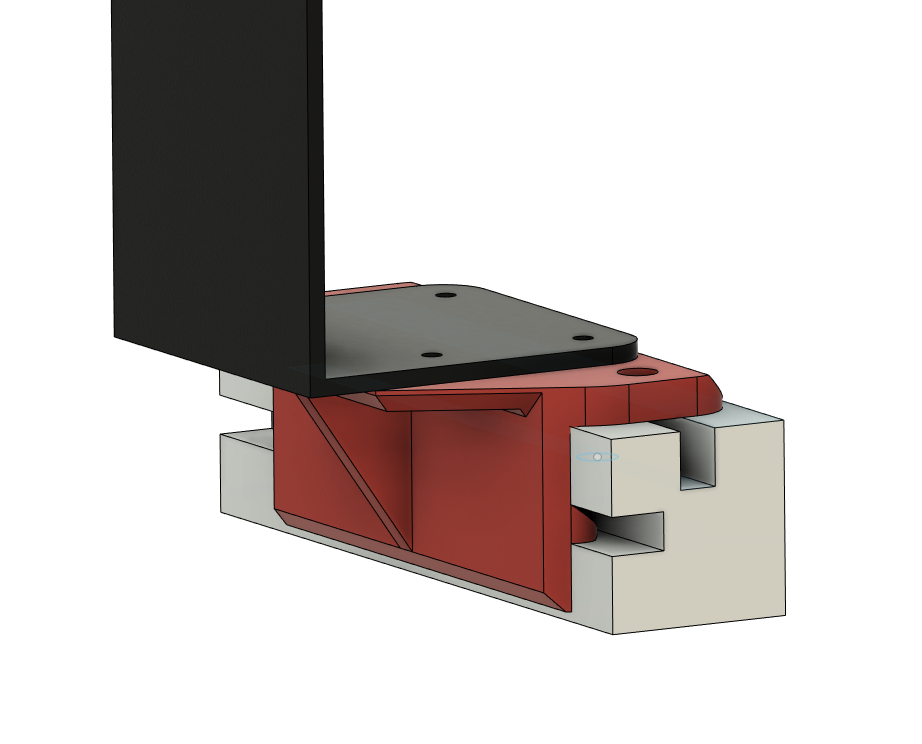

I've been using this simple 8020 plate with a couple lever bolts on each side that I use to allow my pedal deck to slide fore/aft and allow me to lift it out completely.

The only issue is that the Levers are a bit too close together and I have to use the lever release mechanism to tighten them all the way and loosen them. A pretty minor inconvenience.

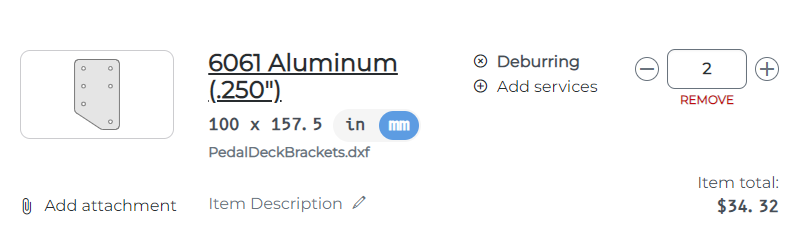

So I designed a slightly wider plate with a bit more space between the bolt holes so I could very easily spin these into place without any interference and I cleaned up the appearance just a bit with 10mm radius corners.

Once again I have plenty of aluminum stock in my shop and I could easily make these myself, but for $34.32 delivered, I would just bevel the holes and finish sand these and I can't justify the shop time to build them myself.

Perfect radiused corners vs. eyeballing them is a plus as well. I feel like I need to find a way to leverage the fact that laser cutting can do a lot more than I'm asking very easily.

I'm going to create a shallow test print to verify the dimensions and make sure that I don't want to do anything more interesting but this is just too easy.

I've been using this simple 8020 plate with a couple lever bolts on each side that I use to allow my pedal deck to slide fore/aft and allow me to lift it out completely.

The only issue is that the Levers are a bit too close together and I have to use the lever release mechanism to tighten them all the way and loosen them. A pretty minor inconvenience.

So I designed a slightly wider plate with a bit more space between the bolt holes so I could very easily spin these into place without any interference and I cleaned up the appearance just a bit with 10mm radius corners.

Once again I have plenty of aluminum stock in my shop and I could easily make these myself, but for $34.32 delivered, I would just bevel the holes and finish sand these and I can't justify the shop time to build them myself.

Perfect radiused corners vs. eyeballing them is a plus as well. I feel like I need to find a way to leverage the fact that laser cutting can do a lot more than I'm asking very easily.

I'm going to create a shallow test print to verify the dimensions and make sure that I don't want to do anything more interesting but this is just too easy.

Last edited:

RCHeliguy

Premium

I ended up widening it just a bit more compared to the 3D test print below. I wasn't accounting for the width at the center of the levers Also widened the holes just a bit 8.5mm each so there is a little wiggle room. The UHMW tape on the bottom creates a small offset and I don't want the bolt threads grinding on the slots.

Sent it off to be laser cut. Once I bevel the holes I think it will look a bit better than what I started with.

Edit: 3 hours after I ordered the parts they went to production. Just loving the instant gratification

Sent it off to be laser cut. Once I bevel the holes I think it will look a bit better than what I started with.

Edit: 3 hours after I ordered the parts they went to production. Just loving the instant gratification

Last edited:

I've always been annoyed with those 'lever bolts' or whatever they're called, for same reason. Often useful in places that they interfere with something else.

But I always wanted to get some of those 'bicycle clamp' style ones I seem to remember you using in the past somewhere? Are they just not strong enough for this situation?

But I always wanted to get some of those 'bicycle clamp' style ones I seem to remember you using in the past somewhere? Are they just not strong enough for this situation?

RCHeliguy

Premium

The issue with the bicycle clamps is mostly that the bolts are way too long. This is repurposing a part designed for a bicycle rather than a part I can order to size. You can use a spacer if you want. They are also a bit more fiddly than the lever arms which I think look better as well.I've always been annoyed with those 'lever bolts' or whatever they're called, for same reason. Often useful in places that they interfere with something else.

But I always wanted to get some of those 'bicycle clamp' style ones I seem to remember you using in the past somewhere? Are they just not strong enough for this situation?

However, I could always take them into the makerspace, run an M8 die up the length of the bolt, chop them to size than run the M8 die out and then clean up the threads.

Last edited:

RCHeliguy

Premium

What service are you using tom complete your cuts? I am thinking of shipping out some designs for my rig. Do they provide any anodize finishing solutions?

I'm using SendCutSend.com and they do offer anodizing and power coating services.

They will also counterbore and thread holes.

RCHeliguy

Premium

Dotting i's and crossing t's.

I've been meaning to create a tool less mount for my Virpil Collective stick, but hadn't gotten around to it. This is not a general purpose mount since it is matches my seat height relative to the top of my frame. This will allow me to secure the stick with a couple M8 knobs which I think is fine for this control.

After this I can only think of one other little thing left to tidy up and it's purely aesthetic and is perfectly functional now. So I'll save that for later.

I've been meaning to create a tool less mount for my Virpil Collective stick, but hadn't gotten around to it. This is not a general purpose mount since it is matches my seat height relative to the top of my frame. This will allow me to secure the stick with a couple M8 knobs which I think is fine for this control.

After this I can only think of one other little thing left to tidy up and it's purely aesthetic and is perfectly functional now. So I'll save that for later.

Thanks for the suggestion. I will give them a try.I'm using SendCutSend.com and they do offer anodizing and power coating services.

They will also counterbore and thread holes.

View attachment 621659

RCHeliguy

Premium

What's very cool it that the process is 100% automated. You drag your DXF file to their site, select the material, thickness and any post processing and they give you an immediate price. So you can price many grades of steel, aluminum, stainless steel or even titanium etc...Thanks for the suggestion. I will give them a try.

Last time I checked my order the status said it was being deburred.

Last edited:

Latest News

-

F1 Manager 2024: Pit Lane Starts & More New Features In Latest UpdateAs the Formula One season starts to draw to a close, F1 Manager 2024 has been hit with a big...

- Connor Minniss

- Updated:

- 2 min read

-

Weekly Races & Twitch Broadcasts: Join The OverTake British GT4 League In ACC!Motorsport's real-world racing series are all winding down as 2024 enters the final stretch -...

- Yannik Haustein

- Updated:

- 2 min read

-

WATCH: Sensit! Aims To Simulate That Seat-Of-The-Pants FeelingOne thing sim racing cannot really replicate well is the sensory feedback drivers get from their...

- Yannik Haustein

- Updated:

- 1 min read

-

Sim Racing Black Friday Deals 2024 - Save An Additional 5% On Asetek Gear With Our Discount CodeBlack Friday is nearly here, but a lot of Sim Racing's top brands and names have already started...

- Connor Minniss

- Updated:

- 8 min read

-

Racing Club Schedule: November 17 - 24A new week means a new set of events in our Racing Club. Here's what's on tap from November 17...

- Yannik Haustein

- Updated:

- 3 min read

-

Macau Grand Prix in Sim Racing: Deserving of More?This weekend is the Macau Grand Prix and whilst a shadow of its former self, this tight street...

- Angus Martin

- Updated:

- 3 min read

-

How One Announcement Quadrupled Forza Horizon 4's Player BaseIt is exactly one month until Forza Horizon 4 will no longer be available to purchase online...

- Angus Martin

- Updated:

- 2 min read