These are the 8mm x 30mm knobs.

https://www.amazon.com/gp/product/B00KHTRNCM

I wasn't trying to build too much suspense. The following is coming on Monday.

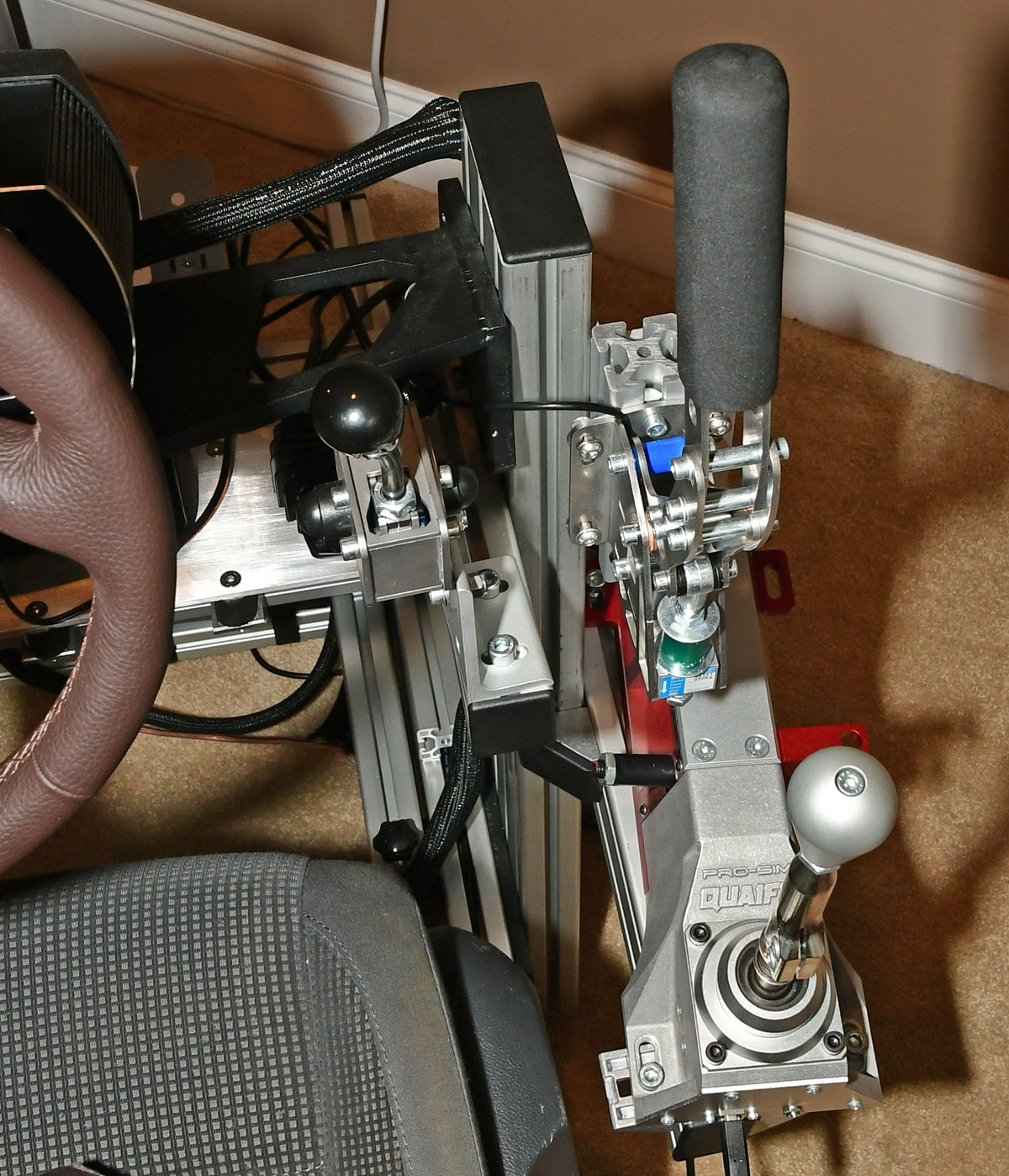

I recently moved my hand brake one profile width to the right so the bracket wouldn't interfere with my wheel deck which I've moved closer to the seat, however the hand brake placement isn't where I want it.

The 30 degree profile is to rotate my handbrake and move it back a bit from where it is in the picture below.

The controls on the right side of my rig are adjusted at an angle based on my right shoulder as a pivot point.

You can see the sequential shifter is counter rotated a bit and the h pattern shift is rotated clockwise. I want to rotate the hand brake a bit clockwise as well. I'm going to slightly recess the 30 degree profile edge a bit behind the 40x120mm vertical profile. The handbrake is a bit too far forward right now. The combination of the 30 degree profile and using two slotted angles that will allow me to pull the profile back a bit moving the handle at an angle to the left and back about an inch which will allow me to drop it a bit lower without interfering with the h pattern shift.

The swivels and side pieces are to reinforce the foot rest. I'll need to round the corners of the side pieces first since there will be a swivel on both sides. Currently I have a neoprene pad at the bottom of the foot rest where it leans against the foot plate. The adjustable angle isn't quite strong enough to hold angle if I press on it with my foot and it is back further than I want it. The swivels are each different parts, one has a horizontal slot rib and the other a vertical slot rib. They will allow me to set and hold the angle I want my foot rest to stay.

The 14mm dia aluminum rods will be the posts for something I will be replacing the headrest with. The only reason I have a headrest on my seat is to separate the shoulder belts. However I need the shoulder belts separated further apart and I would like to raise them so they hit my collar bones at a more comfortable angle.

The VR part of this is that since I got my Valve Index which has more structure on the back of your head I've had to reverse the headrest on my seat which to me looks stupid. That gave me the incentive to replace it. In addition, I want to add a loose drop in headset cable hangar with a lot of range. I also have some blue acrylic rod coming that I'm going to use for the seat belts to slide on, and to hold the headset cable. Acrylic bends easily when heated properly. I may use a bit of African Purple Heart for the structure that holds this together. I still have some design work to do on this.