RCHeliguy

Premium

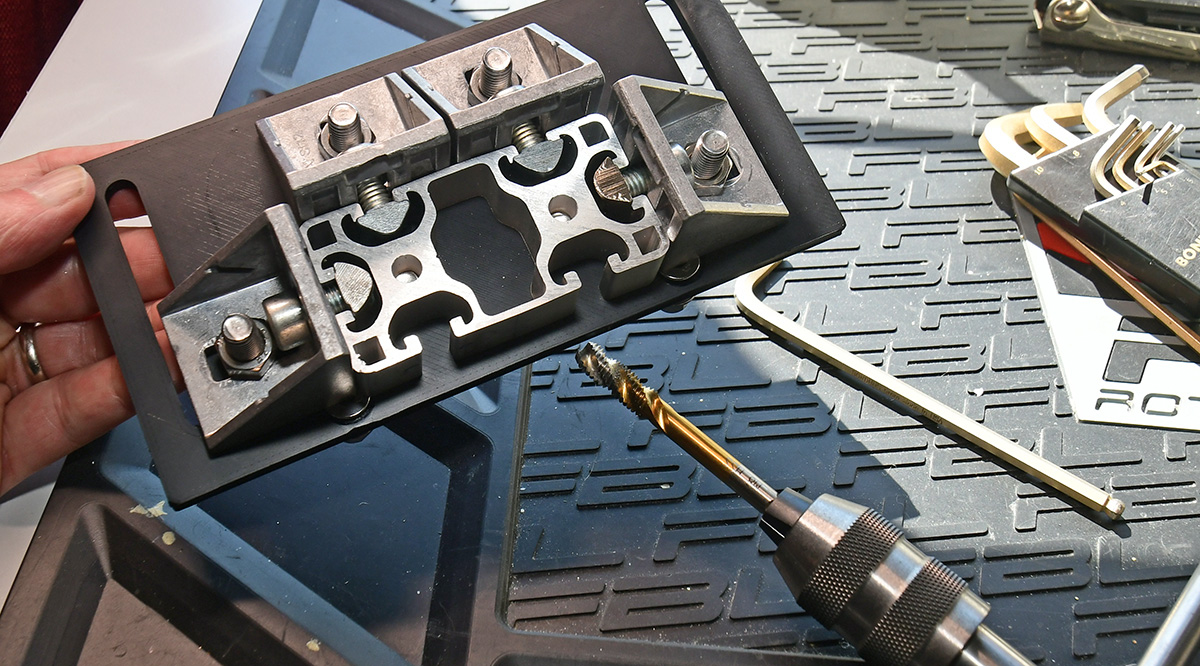

So far so good. I'll need to secure the 6mm bolts to the tactile plate before I can attach the outer corner brackets.

I should have tapped a couple more threads out of one of the holes on this piece of scrap 40x80, but it won't impact my test fitting this.

Bolts right in, but I'll need to through bolt to T-nut in the profile.

I should have tapped a couple more threads out of one of the holes on this piece of scrap 40x80, but it won't impact my test fitting this.

Bolts right in, but I'll need to through bolt to T-nut in the profile.

Last edited: