Sorry to hear you are having issues with your brand new D-box Mark.

From personal experience i know that what ever solution you come up to move your rig, it needs to be quick and effortless.

If it's too much trouble and hassle to move and set it up, you will use it less, especially for a quick play.

A cart with large wheels is still the best option imho. I have been using this solution for years now.

Then you still have to deal with aligning the feet below the actuators, but i believe D-box also a have version which bolts on to the actuator.

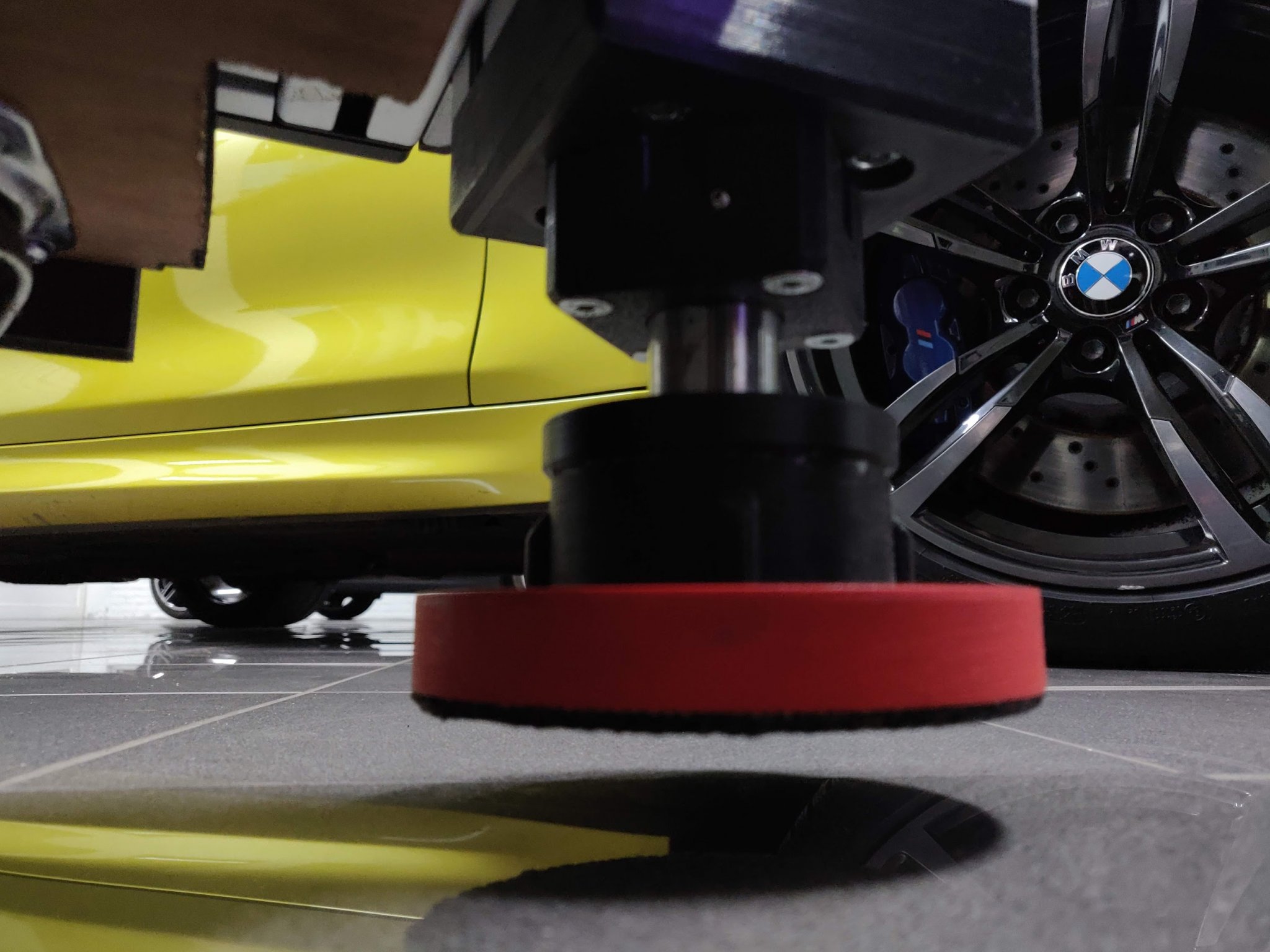

In the end i combined the feet and the plates into one, saving me another minute or so.

Sliding plates may cause severe stress to the D-box actuators over time.

You are putting side way forces on them every time and they might not be designed for that.

From personal experience i know that what ever solution you come up to move your rig, it needs to be quick and effortless.

If it's too much trouble and hassle to move and set it up, you will use it less, especially for a quick play.

A cart with large wheels is still the best option imho. I have been using this solution for years now.

Then you still have to deal with aligning the feet below the actuators, but i believe D-box also a have version which bolts on to the actuator.

In the end i combined the feet and the plates into one, saving me another minute or so.

Sliding plates may cause severe stress to the D-box actuators over time.

You are putting side way forces on them every time and they might not be designed for that.