You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile Driving/Flying Cockpit with Motion and Tactile ( Build )

Are those gloves Sparco Arrow K? I ordered them the other day (same color). How do you like them?

RCHeliguy

Premium

AlpineStars Tech 1-KXAre those gloves Sparco Arrow K? I ordered them the other day (same color). How do you like them?

RCHeliguy

Premium

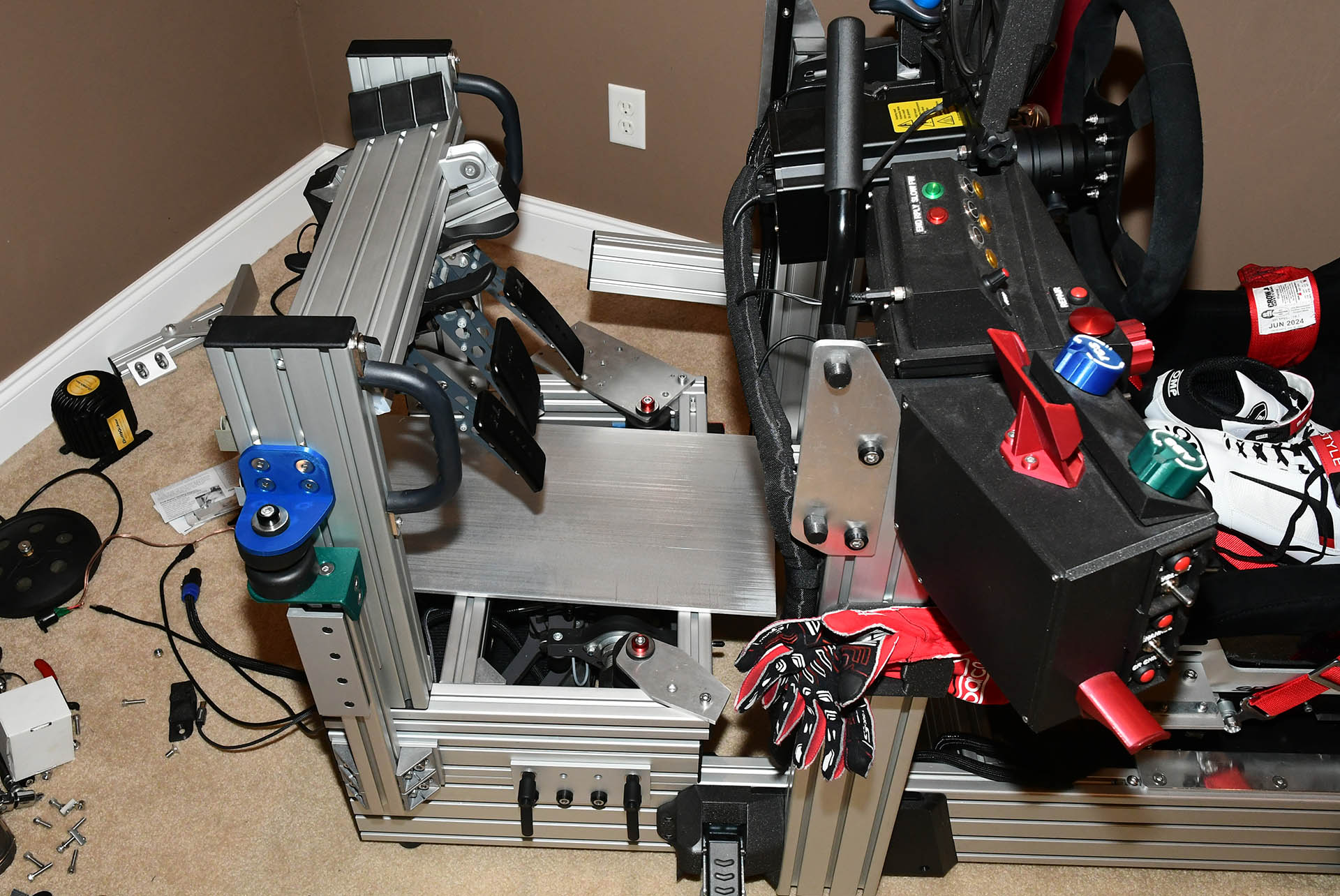

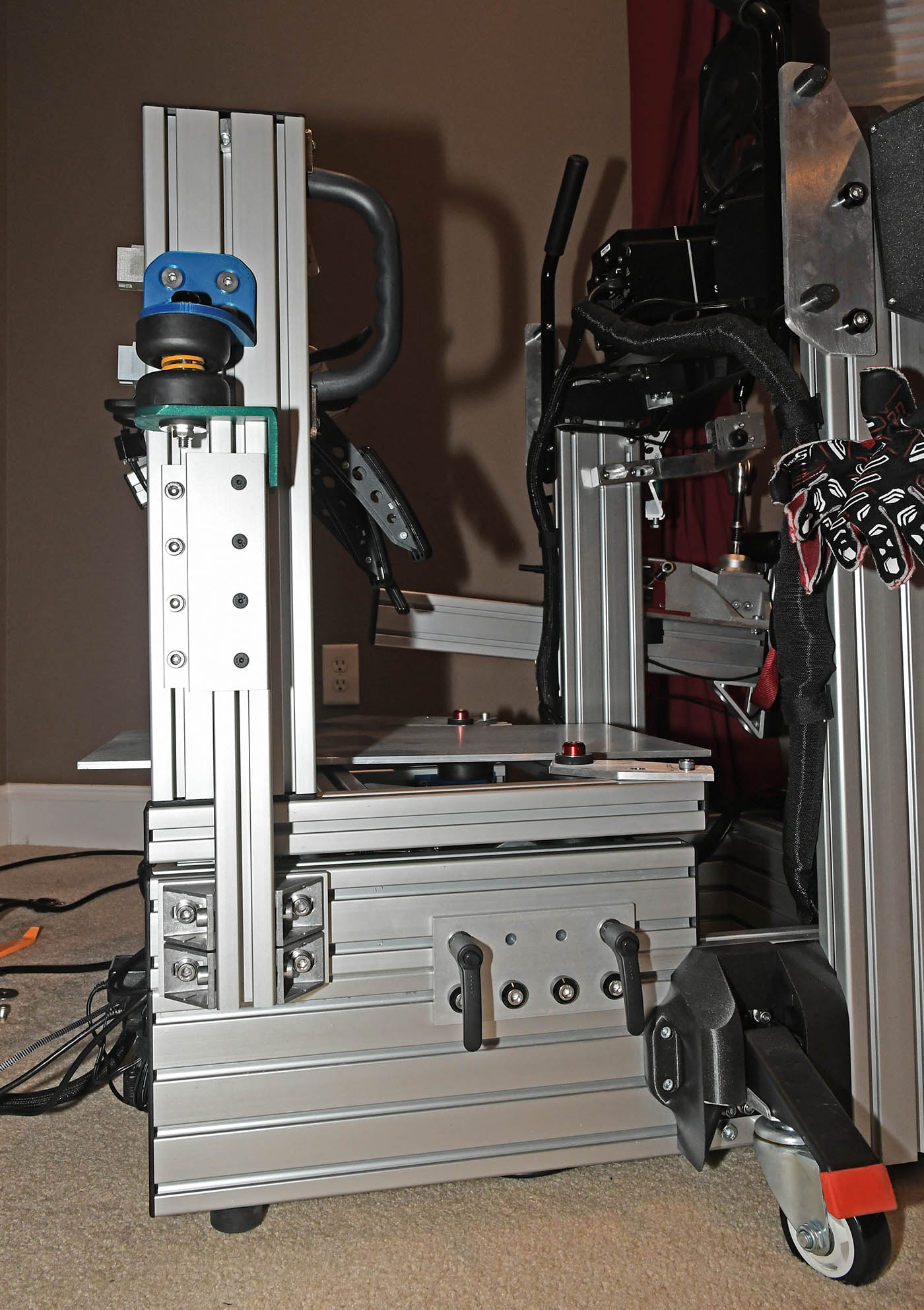

The pedal deck is suspended on the PLA brackets.

The linear bearings are aligned. Vertical motion is smooth.

I tested the vertical supports by themselves with no springs and pulled the pedal deck back as hard as I could. I got about 1/8" of a crack at the very front of the pedal deck. looks pretty rigid

I did reverse the top isolation brackets to make it easier to reach the bolts while adjusting the height.

I couldn't see any deflection under brake pressure, but I'll need to have video watching from the side to confirm. Given the PLA mounts and very weak yellow springs I currently have installed the vertical supports seem to be providing a lot of support. I can still go to blue or red springs depending on how everything feels after I make the aluminum brackets.

The linear bearings are aligned. Vertical motion is smooth.

I tested the vertical supports by themselves with no springs and pulled the pedal deck back as hard as I could. I got about 1/8" of a crack at the very front of the pedal deck. looks pretty rigid

I did reverse the top isolation brackets to make it easier to reach the bolts while adjusting the height.

I couldn't see any deflection under brake pressure, but I'll need to have video watching from the side to confirm. Given the PLA mounts and very weak yellow springs I currently have installed the vertical supports seem to be providing a lot of support. I can still go to blue or red springs depending on how everything feels after I make the aluminum brackets.

Last edited:

they look like arrows, right down to the word sparco on them?AlpineStars Tech 1-KX

RCHeliguy

Premium

I just searched my email history and thought I found them. You could be right. I think I purchased them directly from Sparco. Their labels don't identify them.they look like arrows, right down to the word sparco on them?

I like them, but they do shed white stuff a bit.

Last edited:

RCHeliguy

Premium

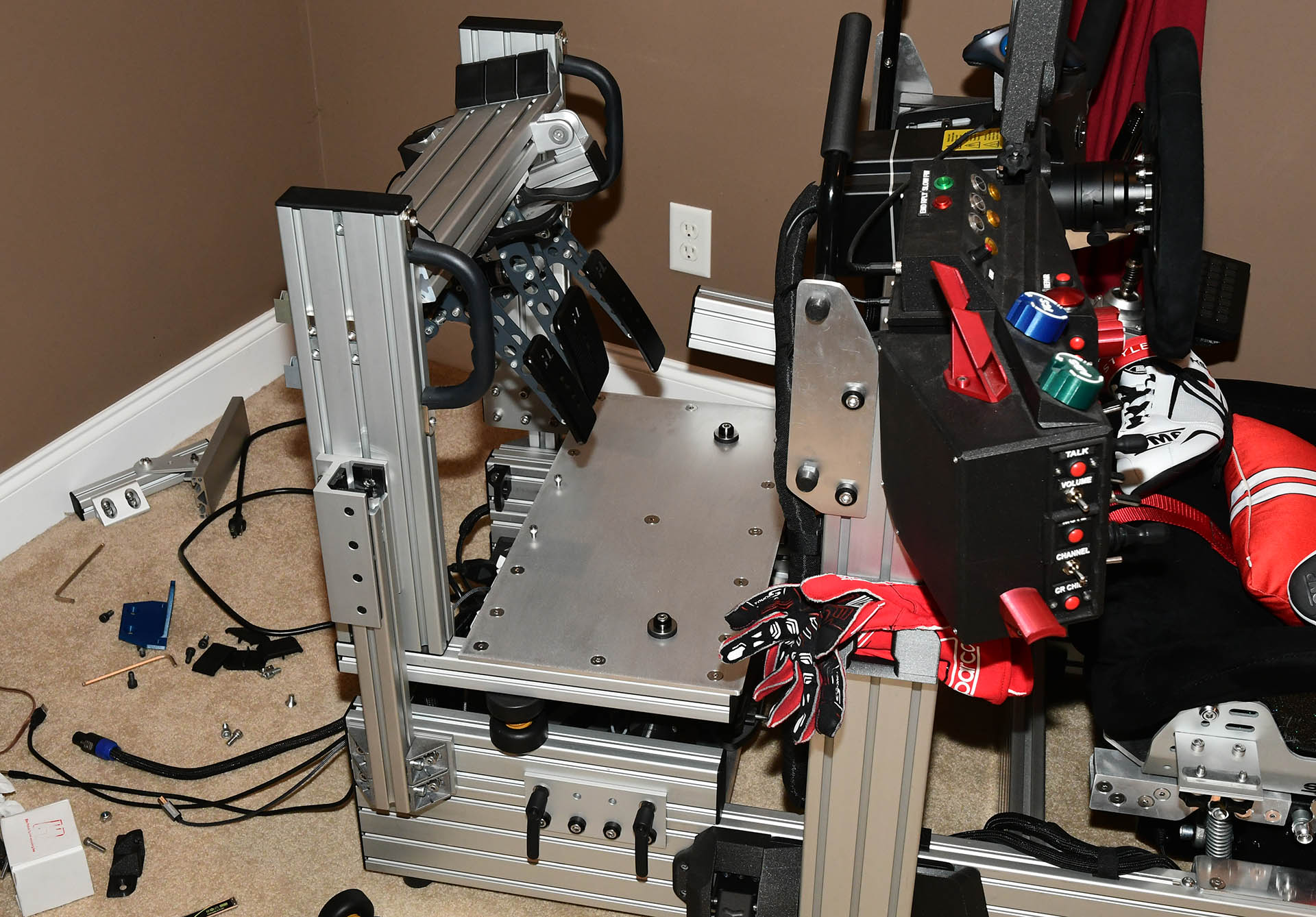

Got the plate mounted and got the garage cleaned up so my wife's happy too.

The plate fits like a glove, but given this is probably my 6th? pedal deck foot plate design, I guess I've had practice.

The action from the linear bearings feels good. I have it lifted up a ways in the picture below and it was not binding at all. For tactile motion it will not be traveling very much, but the fact it can move freely across many inches of travel shows that the bearings are aligned past the accuracy required for this application.

The plate fits like a glove, but given this is probably my 6th? pedal deck foot plate design, I guess I've had practice.

The action from the linear bearings feels good. I have it lifted up a ways in the picture below and it was not binding at all. For tactile motion it will not be traveling very much, but the fact it can move freely across many inches of travel shows that the bearings are aligned past the accuracy required for this application.

Last edited:

RCHeliguy

Premium

The steps involved to get good bevel holes are not hard.

Use a drill press. Mine is a cheap table top version. Get good bits. Use cutting fluid.

1. Through drill the bolt size, M8 for example. I use an 8.5mm bit for beveled bolt holes.

2. Use a good chamfer bit.

3. Set the stop on the drill press for consistent depth. Creep up on the right depth and when the bolt is perfectly flush save that stop point.

Rinse and repeat.

It also helps to precisely measure where the bolts go and use an auto punch to set your bolt hole centers.

If you have a very square piece to start with. Then you can use a caliper to score a line with an offset like 20mm for the centerline of 40 series profile.

For a smooth edge a deburring tool is helpful. I also recently got a chamfering deburring tool as a deburring aid for freshly drilled holes. I just run it around a freshly drilled hole to remove any sharp edges.

For finishing a 100 grit random orbital sander will create a nice speckled finish.

A 220 grit sandpaper with a soft supportive backing run in very parallel fashion will created a nice brushed finish.

For a mirror finish polish and a hand drill with a foam pad works well. A buffing wheel can be helpful.

Use a drill press. Mine is a cheap table top version. Get good bits. Use cutting fluid.

1. Through drill the bolt size, M8 for example. I use an 8.5mm bit for beveled bolt holes.

2. Use a good chamfer bit.

3. Set the stop on the drill press for consistent depth. Creep up on the right depth and when the bolt is perfectly flush save that stop point.

Rinse and repeat.

It also helps to precisely measure where the bolts go and use an auto punch to set your bolt hole centers.

If you have a very square piece to start with. Then you can use a caliper to score a line with an offset like 20mm for the centerline of 40 series profile.

For a smooth edge a deburring tool is helpful. I also recently got a chamfering deburring tool as a deburring aid for freshly drilled holes. I just run it around a freshly drilled hole to remove any sharp edges.

For finishing a 100 grit random orbital sander will create a nice speckled finish.

A 220 grit sandpaper with a soft supportive backing run in very parallel fashion will created a nice brushed finish.

For a mirror finish polish and a hand drill with a foam pad works well. A buffing wheel can be helpful.

Last edited:

RCHeliguy

Premium

All that said. I'm going to stick with my Sprints for the time being.

Well, that didn't age well.

RCHeliguy

Premium

The will is weak... I didn't need them, but I wanted them... <sigh>Why have you ordered ultimate+ pedals per chance?

Last edited:

You are only here once… you can’t take it with you when your gone… you are only here for a fun time, not a long time… (and all the other sayings you can think of)…The will is weak... I didn't need them, but I wanted them... <sigh>

Trust me, you won’t be disappointed…

Last edited:

RCHeliguy

Premium

Poor excuses people use to justify sim purchases.

1. You only live once.

2. You could be wasting your money on drugs, alcohol, gambling.

3. It will improve your lap time. ( LOL! )

I knew I had gone down the hole already. I was watching and re-watching reviews, reading articles. Looking at the dimensions to make sure I could fit them to my rig. I think they they call this "getting the bug".

1. You only live once.

2. You could be wasting your money on drugs, alcohol, gambling.

3. It will improve your lap time. ( LOL! )

I knew I had gone down the hole already. I was watching and re-watching reviews, reading articles. Looking at the dimensions to make sure I could fit them to my rig. I think they they call this "getting the bug".

Latest News

-

Need For Speed Unbound To Add Playable Motorbikes In Vol. 9Throughout the rich thirty-year history of Need For Speed, motorbikes have always evaded the...

- Connor Minniss

- Updated:

- 3 min read

-

Revisiting Our Top 3 2024 FIA WEC Moments in Le Mans UltimateThe 2024 FIA World Endurance Championship may be over but its intense action rests heavy on the...

- Angus Martin

- Updated:

- 6 min read

-

Community Question: Which Car Would You Like To See Brought To Assetto Corsa?Assetto Corsa is renowned for being the most versatile racing simulator on the market with...

- Connor Minniss

- Updated:

- 2 min read

-

"A Lifelong Dream": How OverTake Community Members Tackled The Mantorp 6 HoursSim racing can have a great sense of community. A handful of OverTake members took this one step...

- Yannik Haustein

- Updated:

- 6 min read

-

F1 Manager 2024: Pit Lane Starts & More New Features In Latest UpdateAs the Formula One season starts to draw to a close, F1 Manager 2024 has been hit with a big...

- Connor Minniss

- Updated:

- 2 min read

-

Weekly Races & Twitch Broadcasts: Join The OverTake British GT4 League In ACC!Motorsport's real-world racing series are all winding down as 2024 enters the final stretch -...

- Yannik Haustein

- Updated:

- 2 min read

-

WATCH: Sensit! Aims To Simulate That Seat-Of-The-Pants FeelingOne thing sim racing cannot really replicate well is the sensory feedback drivers get from their...

- Yannik Haustein

- Updated:

- 1 min read