RCHeliguy

Premium

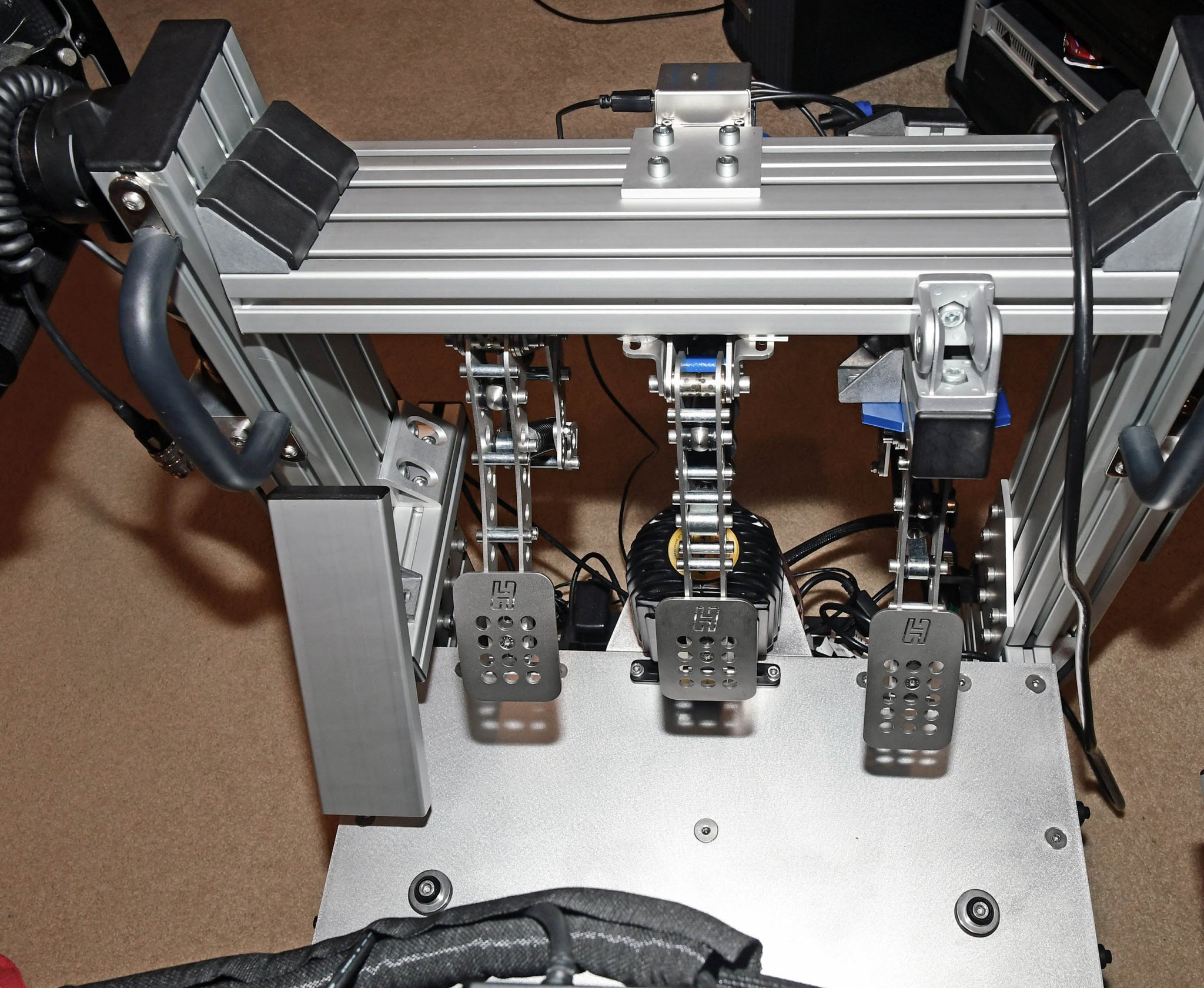

So far I'm not feeling like I'll need the HRS pedal face replacements. In fact I like that the brake pedal face is a bit narrower, but I won't discount that possibility in the future. I'm still liking how the pedal faces feel in general, but the smoother HRS throttle might be a small improvement.

Got my dead pedal dialed better today, probably the first time I've felt like it was exactly right. It is now perfectly comfortable and my foot rests there instinctively. I moved it further to the outer edge so there is no chance of catching my shoe on it if I'm sloppy with the clutch or if someone has really wide feet. There is a bit of an optical illusion here. The clutch pedal is far enough in front of the dead pedal that it will be able to slide over the top of it.

Got my dead pedal dialed better today, probably the first time I've felt like it was exactly right. It is now perfectly comfortable and my foot rests there instinctively. I moved it further to the outer edge so there is no chance of catching my shoe on it if I'm sloppy with the clutch or if someone has really wide feet. There is a bit of an optical illusion here. The clutch pedal is far enough in front of the dead pedal that it will be able to slide over the top of it.

Last edited: