So I finally got to the point, where I can start working on the G-Seat.

Here is my latest progress with the rig in general.

What's important for G-Seat part of the project is tactile installation on the seat, which consists of 3 BK Concert + 1 TST 239, so it's pretty powerful tactile, so I must make sure nothing rattles, this will be challenge as there will be many moving parts.

I'm using Kirkey Aluminium Seat, link is here.

I have 17'' version and it fits me like a glove I'm 168 cm, around 66 kg, quite thin with broader shoulders and it's so so, especially with the G-Seat paddles. I'm striving to take around 2,5 cm of space from the internal volume with paddles.

I'm 168 cm, around 66 kg, quite thin with broader shoulders and it's so so, especially with the G-Seat paddles. I'm striving to take around 2,5 cm of space from the internal volume with paddles.

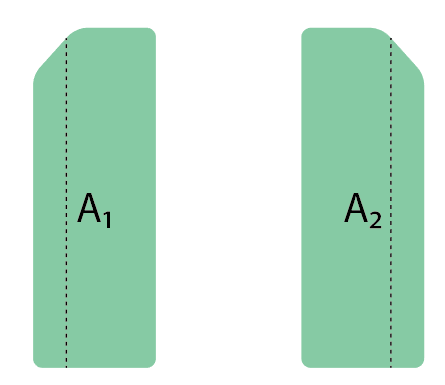

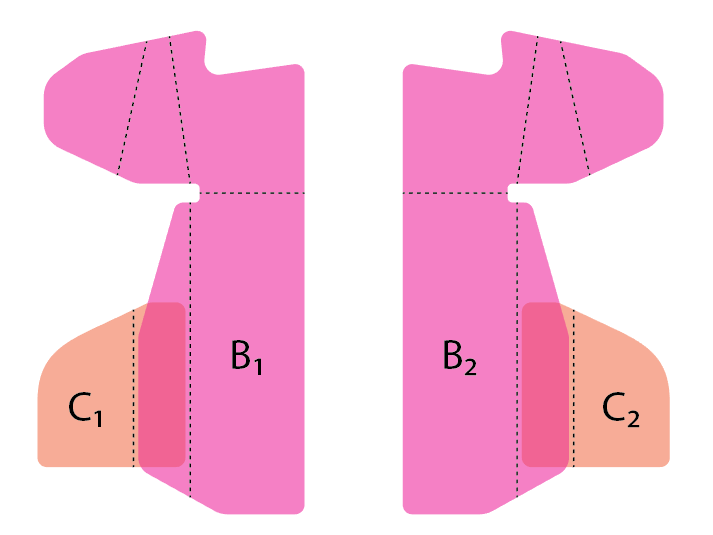

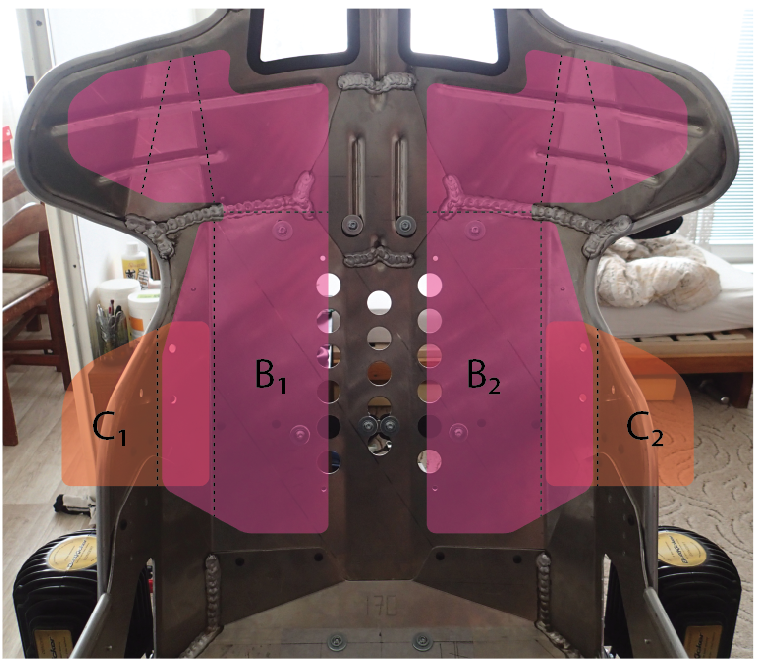

Here is the parts overview:

A) Bottom paddles - with big space between them - I don't want to simulate heave, maybe just a little, but it's intended mainly as pressure from the sides.

B) Main back paddles - narrower gap between to allow for some pressure during acceleration.

C) Additional back paddles for sides - just for thin guys, I made them removable to allow someone with bigger butt to fit in there

I spent day and half measuring etc., here are some images of progress:

Now when I printed it on A3:

And with additional paddle from the side:

I'm really happy it worked so well! I just have to correct 2 lines where the plate would be bent and that's it! I don't need to tweak the shape any more, it fits perfectly!

I will be probably using 4x ASME-04A servos for 4 paddles and 2 for seat belt tensioner.

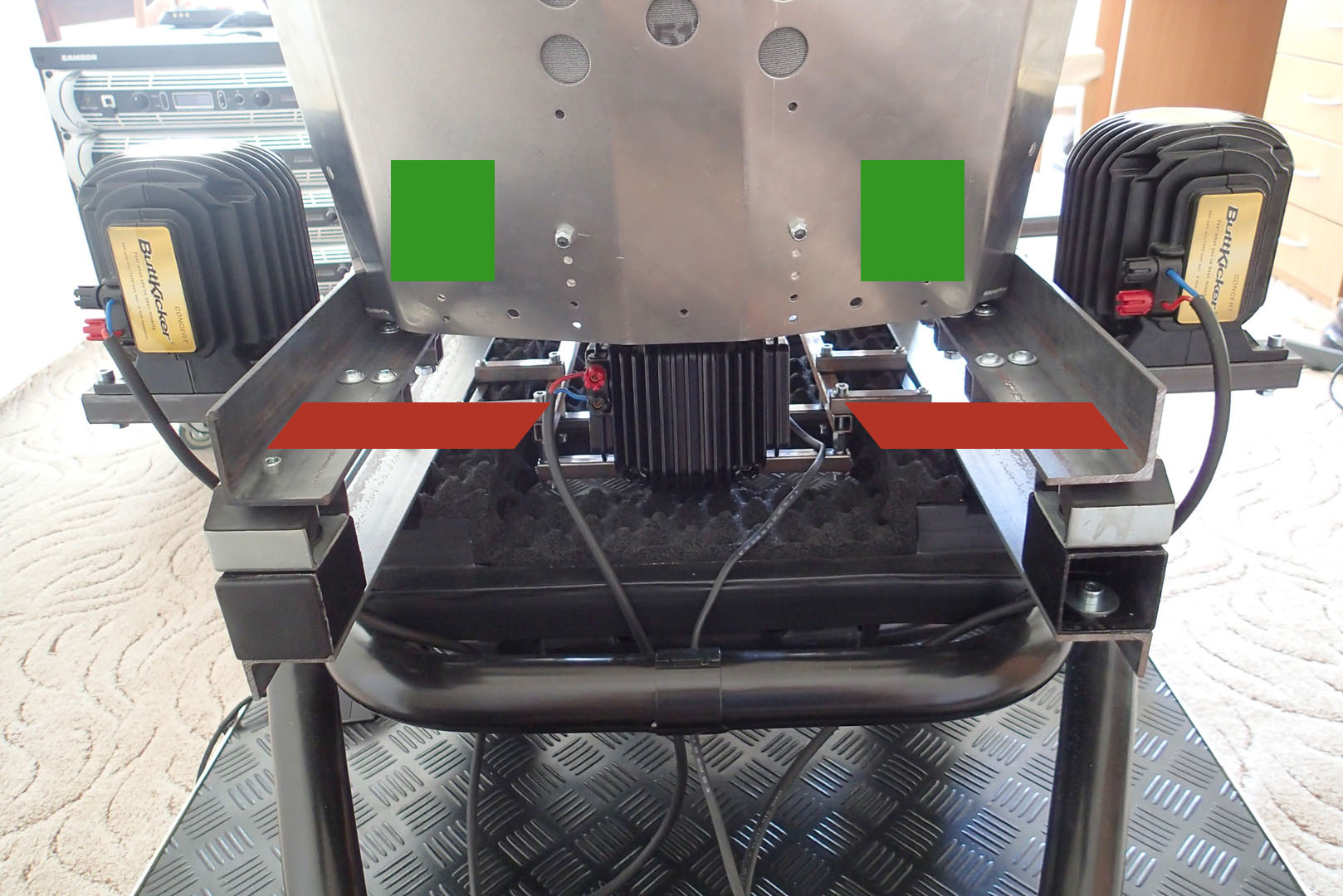

The servos for bottom paddles will be located on red profiles like pictured below, on these profiles will be also servos for seatbelt fastener.

Servos for back paddles will be mounted to the seat.

The servos axles are goint to be extended by this connection - 8 mm to 12 mm, for 12 mm shafts I use aluminium hollow shaft with 2 mm thick wall.

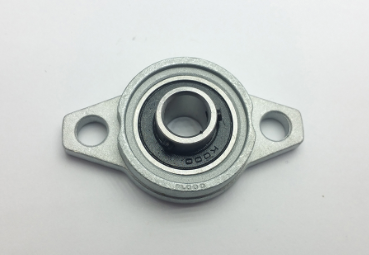

The shaft will be like 0,5 m long, so at the end, it will be fixed in ball bearing with housing connected to the seat to prevent shaft bending.

Along the way there are going to be 2 points on each shaft with fixed clamp.

Here is my latest progress with the rig in general.

What's important for G-Seat part of the project is tactile installation on the seat, which consists of 3 BK Concert + 1 TST 239, so it's pretty powerful tactile, so I must make sure nothing rattles, this will be challenge as there will be many moving parts.

I'm using Kirkey Aluminium Seat, link is here.

I have 17'' version and it fits me like a glove

Here is the parts overview:

A) Bottom paddles - with big space between them - I don't want to simulate heave, maybe just a little, but it's intended mainly as pressure from the sides.

B) Main back paddles - narrower gap between to allow for some pressure during acceleration.

C) Additional back paddles for sides - just for thin guys, I made them removable to allow someone with bigger butt to fit in there

I spent day and half measuring etc., here are some images of progress:

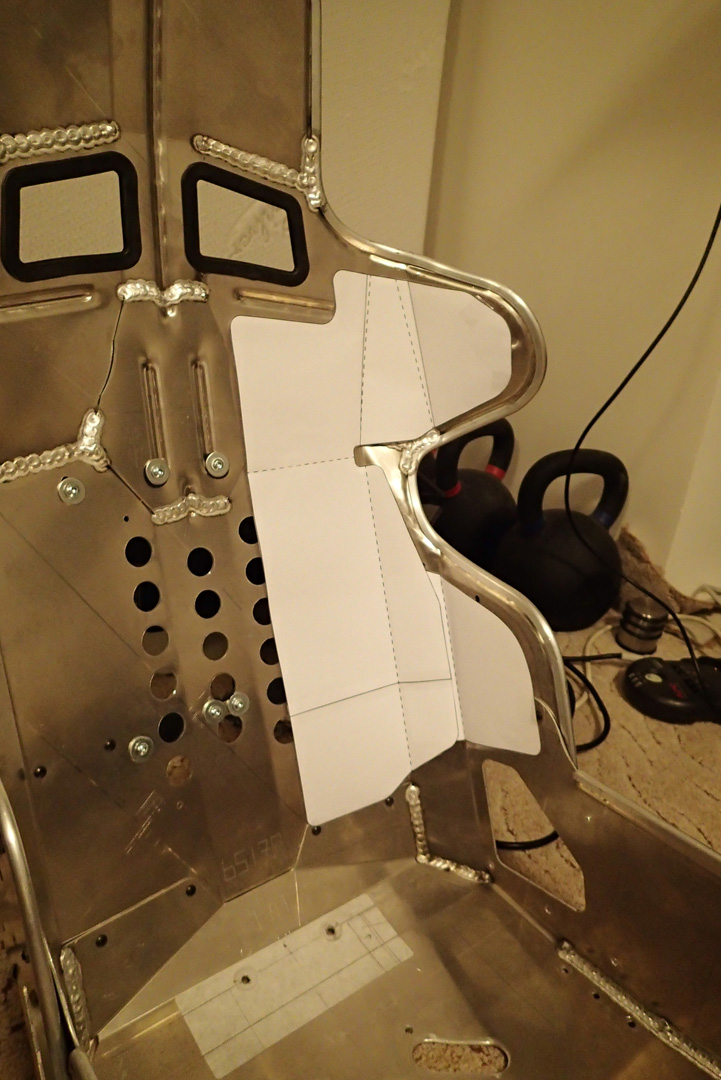

Now when I printed it on A3:

And with additional paddle from the side:

I'm really happy it worked so well! I just have to correct 2 lines where the plate would be bent and that's it! I don't need to tweak the shape any more, it fits perfectly!

I will be probably using 4x ASME-04A servos for 4 paddles and 2 for seat belt tensioner.

The servos for bottom paddles will be located on red profiles like pictured below, on these profiles will be also servos for seatbelt fastener.

Servos for back paddles will be mounted to the seat.

The servos axles are goint to be extended by this connection - 8 mm to 12 mm, for 12 mm shafts I use aluminium hollow shaft with 2 mm thick wall.

The shaft will be like 0,5 m long, so at the end, it will be fixed in ball bearing with housing connected to the seat to prevent shaft bending.

Along the way there are going to be 2 points on each shaft with fixed clamp.

Last edited: