Hi All!

I am starting this log as a story of my journey in upgrading my outdated desk to proper sim rig. In the process I stumbled across a lot of issues and questions, for which I could not find detailed information and pictures (as far as I saw it is quite common for the subject). This I decided to write up a build log with all that was done.

First of all, here is what I started with:

This is my old gaming desk, which was used both for sim racing and work (I work home office). The biggest issue with it was that when I switched to Fanatec setup it was not adequate support any more and I had to start thing of something more stable. Also another issue was that every evening after finishing work I had to mount the wheel and handbrake to drive, then had to remove them in the morning. This is not so big deal, but some evening I was just too laze to do it so I wouldn't play.

First I started investigating buying pre-fabricated rig, but all of them wouldn't fit my needs. As I am long years experienced computer modder, of course decided to pursue the DIY path. Lucky for me I was able to source all materials locally and they were rather cheap - I was way under the pre-made rig prices.

First of all started by listing all the requirements:

1. Completely DIY scratch build by my design

2. Will be used both for work and sim racing

3. Seat has to be high so I can rest my feet on ground (as I am 1.90m tall this required seat height about 40-50cm above ground)

4. All driving gear should be mounted permanently and not get in the way of monitors while in work mode (Fanatec coming with QR system is great advantage)

5. Ideally pedals will be mounted so I can stretch my legs and rest on them while working

6. Integrated monitor stand is preferred

7. Shifter, handbrake should be mounted in such way that mouse can be used all the time in comfortable position (work mode)

8. Seat should have sliders to be comfortable for other people, also for easier access

Having this in mind, I went ahead and downloaded MayCad (apparently the preferred tool for designing with Alu extrusion profiles). Right now I do not have the original design at hand, but either way we will get to this stage later in the build log.

For now let's start with a Teaser picture of the current state of the rig:

After building the first version, I could not stop so added the following:

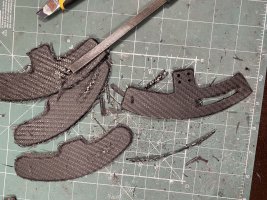

1. Made new gear / info displays (I am using Simhub)

2. At some point switched to complete Fanatec setup (pedals and shifter)

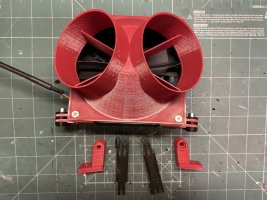

3. Added a wind sim

4. Added 4 Aura bass shakers in chassis mode for tactile feedback

5. Added addressable RGB lighting showing REVs and light effects

Here is short video demoing the RGB lighting:

Of course I have other upgrades planned, but they will be done later on after the summer ends:

1. I have 4 more Dayton DAEX32EP-4 exciters, which will have to mount for additional effects - still have not decided where to put them exactly.

2. Will change monitor setup - actually already got whatever I need, but no time to install it - will be updated later when I get to it

3. Will have to upgrade my PC - I am still using Athlon FX 8350 with GeForce 1060 and it is getting very outdated

4. Will be retiring my modded PC case as it does not provide easy access. Already made preliminary design how all will look

In the upcoming days I will be posting replies on the topic with a lot of pictures and technical details following the extensive collection of photos I took in the process and also sharing all the technical solutions I came up.

Hope this helps others and you enjoy my story,

Cheers,

Stoyan

I am starting this log as a story of my journey in upgrading my outdated desk to proper sim rig. In the process I stumbled across a lot of issues and questions, for which I could not find detailed information and pictures (as far as I saw it is quite common for the subject). This I decided to write up a build log with all that was done.

First of all, here is what I started with:

This is my old gaming desk, which was used both for sim racing and work (I work home office). The biggest issue with it was that when I switched to Fanatec setup it was not adequate support any more and I had to start thing of something more stable. Also another issue was that every evening after finishing work I had to mount the wheel and handbrake to drive, then had to remove them in the morning. This is not so big deal, but some evening I was just too laze to do it so I wouldn't play.

First I started investigating buying pre-fabricated rig, but all of them wouldn't fit my needs. As I am long years experienced computer modder, of course decided to pursue the DIY path. Lucky for me I was able to source all materials locally and they were rather cheap - I was way under the pre-made rig prices.

First of all started by listing all the requirements:

1. Completely DIY scratch build by my design

2. Will be used both for work and sim racing

3. Seat has to be high so I can rest my feet on ground (as I am 1.90m tall this required seat height about 40-50cm above ground)

4. All driving gear should be mounted permanently and not get in the way of monitors while in work mode (Fanatec coming with QR system is great advantage)

5. Ideally pedals will be mounted so I can stretch my legs and rest on them while working

6. Integrated monitor stand is preferred

7. Shifter, handbrake should be mounted in such way that mouse can be used all the time in comfortable position (work mode)

8. Seat should have sliders to be comfortable for other people, also for easier access

Having this in mind, I went ahead and downloaded MayCad (apparently the preferred tool for designing with Alu extrusion profiles). Right now I do not have the original design at hand, but either way we will get to this stage later in the build log.

For now let's start with a Teaser picture of the current state of the rig:

After building the first version, I could not stop so added the following:

1. Made new gear / info displays (I am using Simhub)

2. At some point switched to complete Fanatec setup (pedals and shifter)

3. Added a wind sim

4. Added 4 Aura bass shakers in chassis mode for tactile feedback

5. Added addressable RGB lighting showing REVs and light effects

Here is short video demoing the RGB lighting:

Of course I have other upgrades planned, but they will be done later on after the summer ends:

1. I have 4 more Dayton DAEX32EP-4 exciters, which will have to mount for additional effects - still have not decided where to put them exactly.

2. Will change monitor setup - actually already got whatever I need, but no time to install it - will be updated later when I get to it

3. Will have to upgrade my PC - I am still using Athlon FX 8350 with GeForce 1060 and it is getting very outdated

4. Will be retiring my modded PC case as it does not provide easy access. Already made preliminary design how all will look

In the upcoming days I will be posting replies on the topic with a lot of pictures and technical details following the extensive collection of photos I took in the process and also sharing all the technical solutions I came up.

Hope this helps others and you enjoy my story,

Cheers,

Stoyan

Last edited: