You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Slow rig build

- Thread starter AccAkut

- Start date

-

- Tags

- dd wheel diy pedals rig

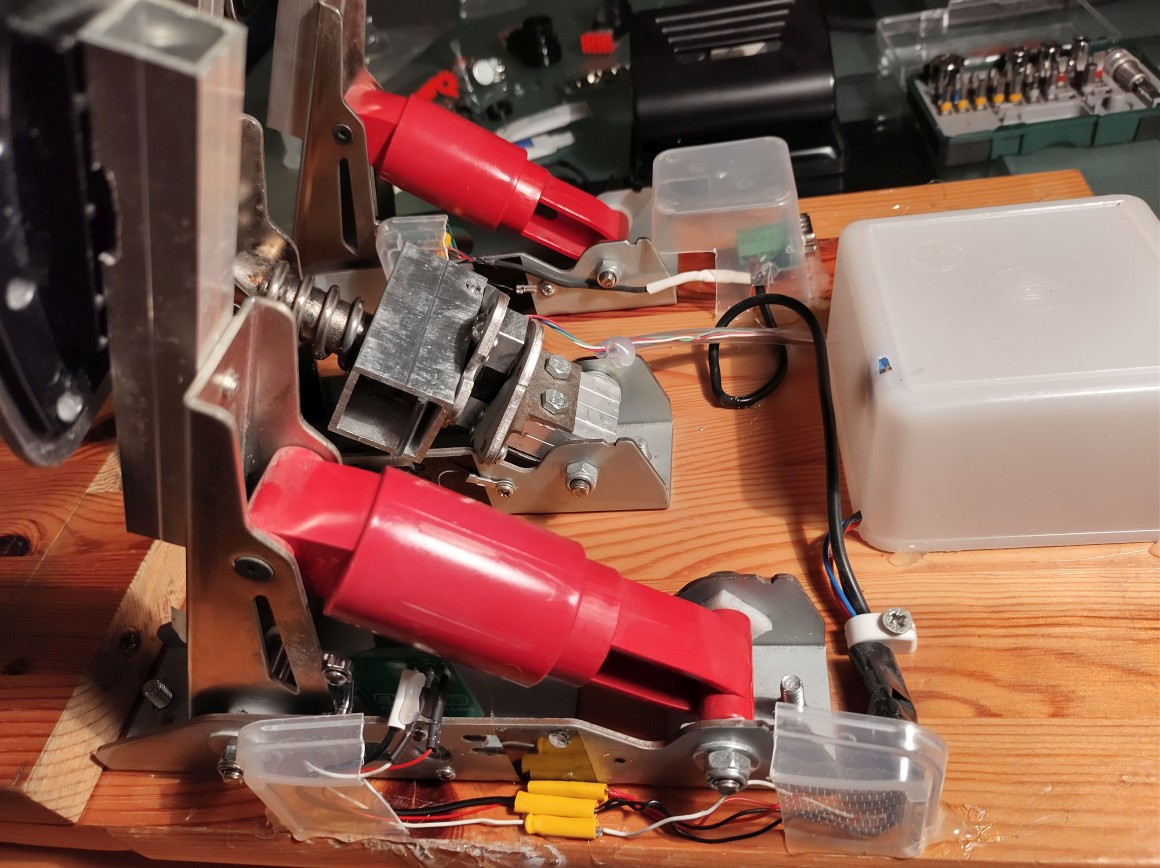

Wired up. And it works!

I again underestimated just how much volume wiring needs. Redid half of it. all the grounds, halfway through with thinner wire.

I use Dupont connectors. Got given the advice to just solder everything directly onto the board, but thats a job for someone with more experience. I'll design a cover for these back pockets and have them printed too

Almost designed myself into a corner by forgetting that I not only need access to the securing pin, but also to slide the wheel of the boss sideways.. luckily it works in this orientation, but only just

Did drive a whole bunch of laps with it last night, these paddles do feel really good. Good trigger point, perfect reach, fast, quiet. Finally I can drive races with both hands on the wheel at all times.. and actually enjoy the SC2 in full fidelity.

Michael Krone

Premium

Im enjoying following this, I really like those paddles but I have a question about your pedals.. What did you use to lengthen them?

Im enjoying following this, I really like those paddles but I have a question about your pedals.. What did you use to lengthen them?

Thanks! Its simple aluminium profiles I found at the hardware store. Held up without issue for close to ten year now. Just screwed to the holes the pads screwed into originally. Its not totally ideal as my feet often touch on those black edges, could probably round those out.

Last edited:

Michael Krone

Premium

Thank you.

Michael Krone

Premium

Soo.. Im in the process of doing this and it just occurred to me, im going to need some stronger springs. Any suggestions?

Had to look up my old thread on the LFS forums. I calculated the strength of the stock brake spring of the G25 pedal, R = 2,8 N/mm, and with that as base line I ordered a bouquet of springs with strength above that from an industrial supplier (I used "Gutekunst" (https://www.federnshop.com/en/) but you could probably find one closer to your place). And then just mixed and matched till I found a combination I liked. I think I used at least R = 5 N/mm. And later on DIYed my own loadcell brake.

@Michael Krone

@Michael Krone

Last edited:

Michael Krone

Premium

Awesome man, thank you!

btw I think I need to take those pedals apart, had heavy spiking last night... it's a bit of a jinx, anytime I tell someone about hardware "never missing a beat" it breaks the next dayAwesome man, thank you!

Michael Krone

Premium

Lol same and same, my clutch is spiking now.

Gotta say that extra small amount of travel made an incredible difference. I had thought I was at my braking point limit. Im finding myself braking sometimes two car lengths further and can feel I have so much more to go. Everything is so much more controllable and connected feeling.

Gotta say that extra small amount of travel made an incredible difference. I had thought I was at my braking point limit. Im finding myself braking sometimes two car lengths further and can feel I have so much more to go. Everything is so much more controllable and connected feeling.

I have the 3DRAP poti kit, it also replaces the stock plastic cogwheels with "new" 3D printed ones that have a different diameter and tooth count.. and looking at it they are not build to last, lots of play from the plastic deforming and rubbing apart. My brake is build from loadcell sensors of a Wii Fit balance board I got dirt cheap, the mechanism around it is all metal, and it holds up fine so far.. so I'l probably look into replacing throttle and clutch in the nearer future... there always something to do with rig stuffLol same and same, my clutch is spiking now.

Gotta say that extra small amount of travel made an incredible difference. I had thought I was at my braking point limit. Im finding myself braking sometimes two car lengths further and can feel I have so much more to go. Everything is so much more controllable and connected feeling.

The "Nintendo" brake:

...looking at the mechanism of the G25 pedals, which I actually quite like as it's simple... could one convert that to use linear potentiometers...?

Found and ordered something... I'll be back.

Last edited:

Time to update the Frankenpedals

as they were with the 3DRap poti kit... even with my occasional use, it did not hold up well, the printed plastic is just not up to the job, even tho I added extra glue and grease. The teeth just wore off quick and both clutch and throttle were more and more imprecise due to it. And yes I did give everything a good clean while I was at it.

In with the "Potentiometer Upgrade Kit" from axc-sim.com. Bit expensive for what it (plus import tax, thanks Brexit

In with the "Potentiometer Upgrade Kit" from axc-sim.com. Bit expensive for what it (plus import tax, thanks Brexit  ), probably mostly due to the small aluminium spring arm being CNC fabricated, but we'll see how well it works. Rather ingenious use of all the existing holes and space, translating the pedal rotation into an (almost) linear motion.

), probably mostly due to the small aluminium spring arm being CNC fabricated, but we'll see how well it works. Rather ingenious use of all the existing holes and space, translating the pedal rotation into an (almost) linear motion.

Installed, with some more "cable guards" fabricated from whatever plastic I had laying around. It looks like **** but worked fine for close to ten years now in its various stages.

as they were with the 3DRap poti kit... even with my occasional use, it did not hold up well, the printed plastic is just not up to the job, even tho I added extra glue and grease. The teeth just wore off quick and both clutch and throttle were more and more imprecise due to it. And yes I did give everything a good clean while I was at it.

Installed, with some more "cable guards" fabricated from whatever plastic I had laying around. It looks like **** but worked fine for close to ten years now in its various stages.

Latest News

-

Racing Club Schedule: November 17 - 24A new week means a new set of events in our Racing Club. Here's what's on tap from November 17...

- Yannik Haustein

- Updated:

- 3 min read

-

Macau Grand Prix in Sim Racing: Deserving of More?This weekend is the Macau Grand Prix and whilst a shadow of its former self, this tight street...

- Angus Martin

- Updated:

- 3 min read

-

How One Announcement Quadrupled Forza Horizon 4's Player BaseIt is exactly one month until Forza Horizon 4 will no longer be available to purchase online...

- Angus Martin

- Updated:

- 2 min read

-

Assetto Corsa EVO New Car Configurator In The PipelineAfter this year's sim Racing Expo, the excitement around Assetto Corsa EVO has continued to...

- Connor Minniss

- Updated:

- 2 min read

-

Steering Wheel Showdown: Which Wheel Would You Like A Sim Racing Version Of?Sim racers have plenty of choice when it comes to hardware. There are a number of cool steering...

- Yannik Haustein

- Updated:

- 2 min read

-

Gran Turismo 7: Yamauchi Teases New Cars For Update 1.53It is that time again when Gran Turismo series producer Kazunori Yamauchi teases us with an...

- Luca Munro

- Updated:

- 5 min read

-

Automobilista 2: Incoming DLC Will Have Free Trial PeriodWith the big v1.6 update, plenty of new content is coming to Automobilista 2. Players who are on...

- Yannik Haustein

- Updated:

- 2 min read