RCHeliguy

Premium

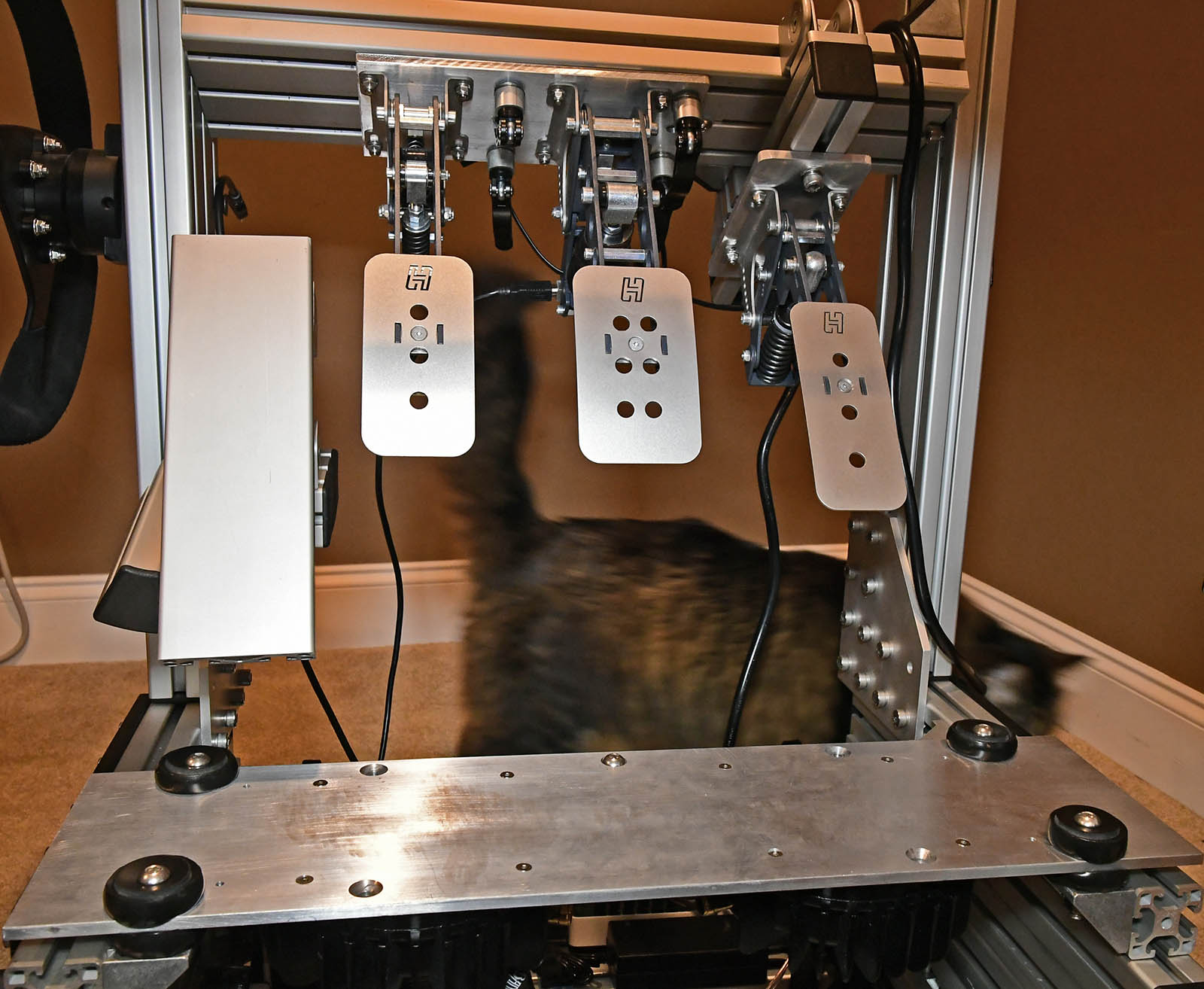

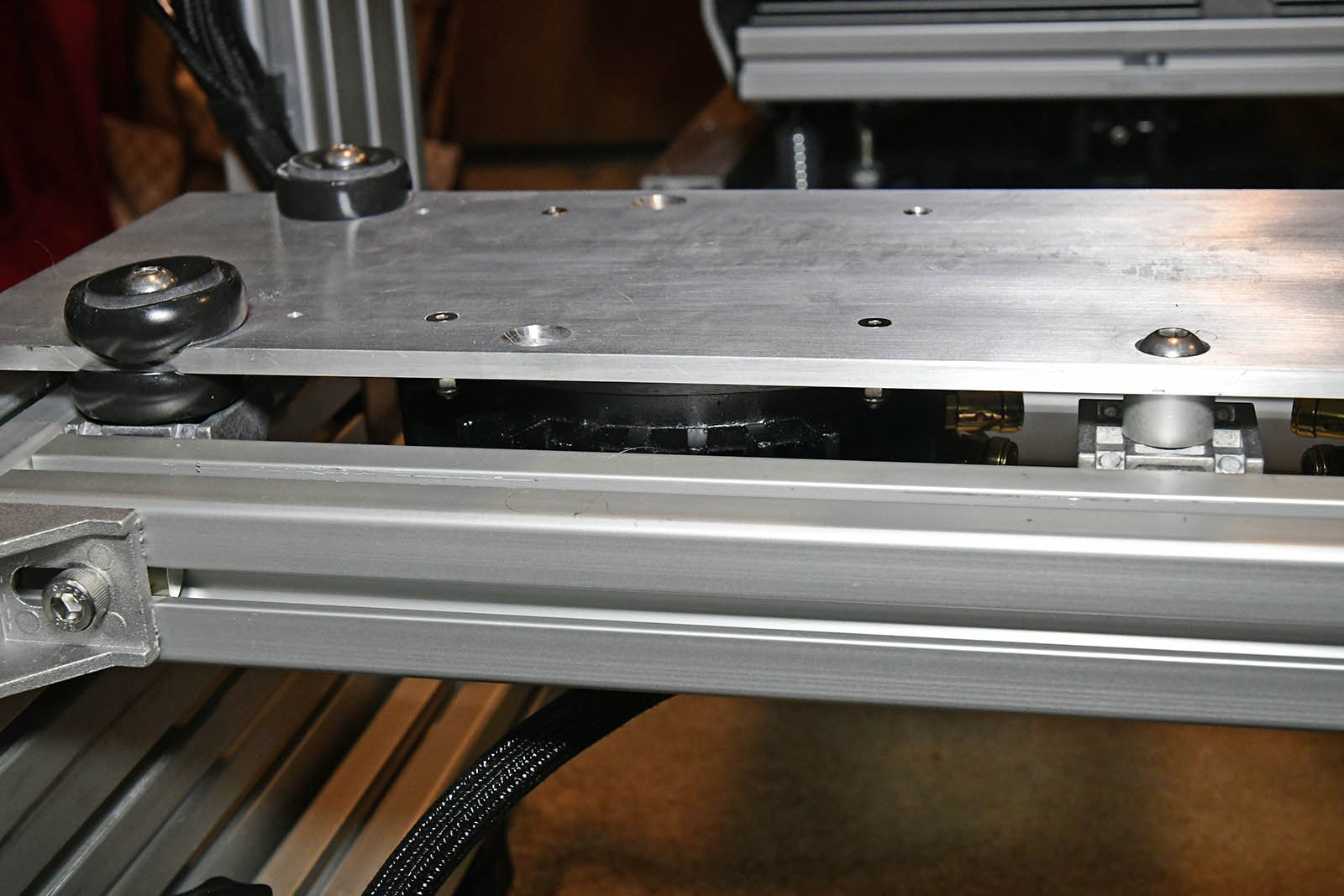

I mounted 1/2" thick 30 durometer Sorbothane cushions on all 4 corners using 1/8" rubber washers on the top and bottom since Sorbothane is sticky gooey and I hard mounted the front center of the plate against a 3/4" spacer cylindrical spacer.

The combination works surprisingly well. The plate isn't moving horizontally in any way I can feel while braking. Having it hard mounted near where my foot is while braking helps, but because the footplate is sandwiched between the sorbothane pieces it as room to move both up and down without any major resistance on both sides and the effect is good.

I've re-positioned and mounted my dead pedal again. It fits easily behind the clutch pedal when I slide the clutch and brake to the left.

So far I'm pretty happy with it. I need to get two nuts on the back so I can lock them together, so they can't come loose. This is not a solution that you can tighten down hard enough to hold with a lock washer. I think I'll need to use locknuts, but I wanted to make sure it was right before I put those in place.

The combination works surprisingly well. The plate isn't moving horizontally in any way I can feel while braking. Having it hard mounted near where my foot is while braking helps, but because the footplate is sandwiched between the sorbothane pieces it as room to move both up and down without any major resistance on both sides and the effect is good.

I've re-positioned and mounted my dead pedal again. It fits easily behind the clutch pedal when I slide the clutch and brake to the left.

So far I'm pretty happy with it. I need to get two nuts on the back so I can lock them together, so they can't come loose. This is not a solution that you can tighten down hard enough to hold with a lock washer. I think I'll need to use locknuts, but I wanted to make sure it was right before I put those in place.