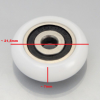

I tried the nylon bearings, but they are too thick, so they didn't fit. I might order different ones and let you guys know how that worked out.

I'm only 6 days late, but didn't forgot ya.

I opened the files and ready to tune.

Quick questions tho;

- Size of your bearing ?

- Do you want the case or the retainer alone ?

(i'd try the retainer alone first, see if it fits; but you tell me)

Bitacaia, for how long have you been using Fusion ?

Damn man, your files are clean and complete !

I've been using it for a few weeks now, coming from SW, and i struggle with all those parts in one.

But once i got the hang of it, it's really nice to use.

Thanks for sharing the files BTW !