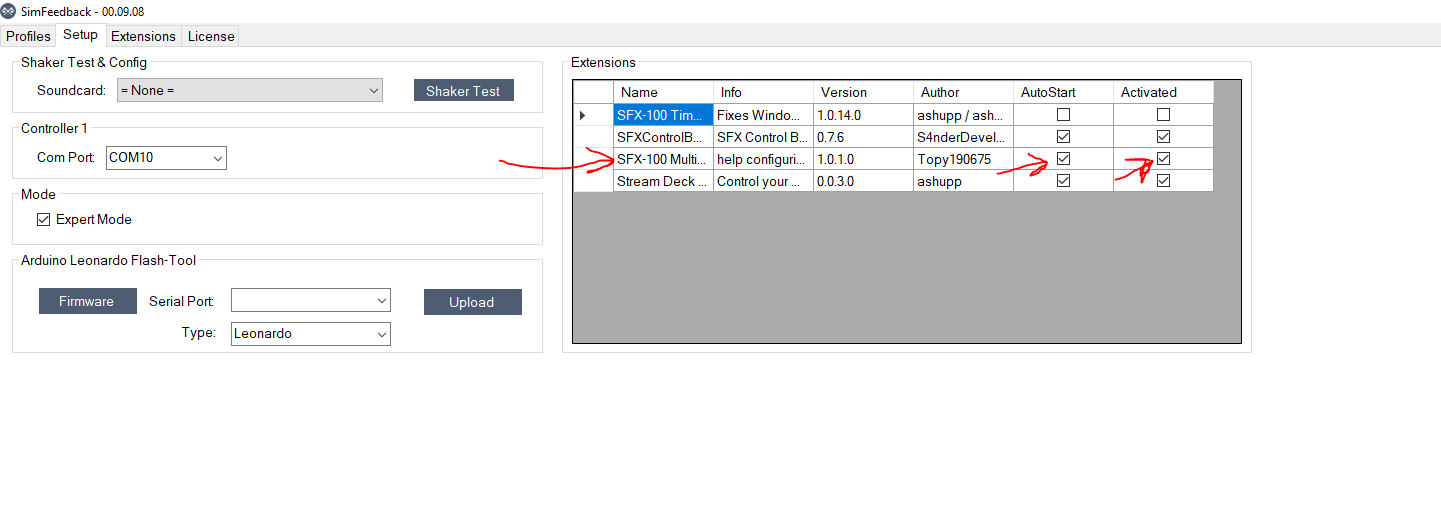

@Andy J I just installed the Mcsetupctrl extension. For me it works perfectly. Just unzip the folder into the "extension" folder in the Simfeedback main directory. Then activate the plugin (see screenshot). Make a restart of Simfeedback and then you should see it in the "Extension" tab (see below).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hoernle's Belt Tensioner - Detailed Build Instructions

- Thread starter Hoernle

- Start date

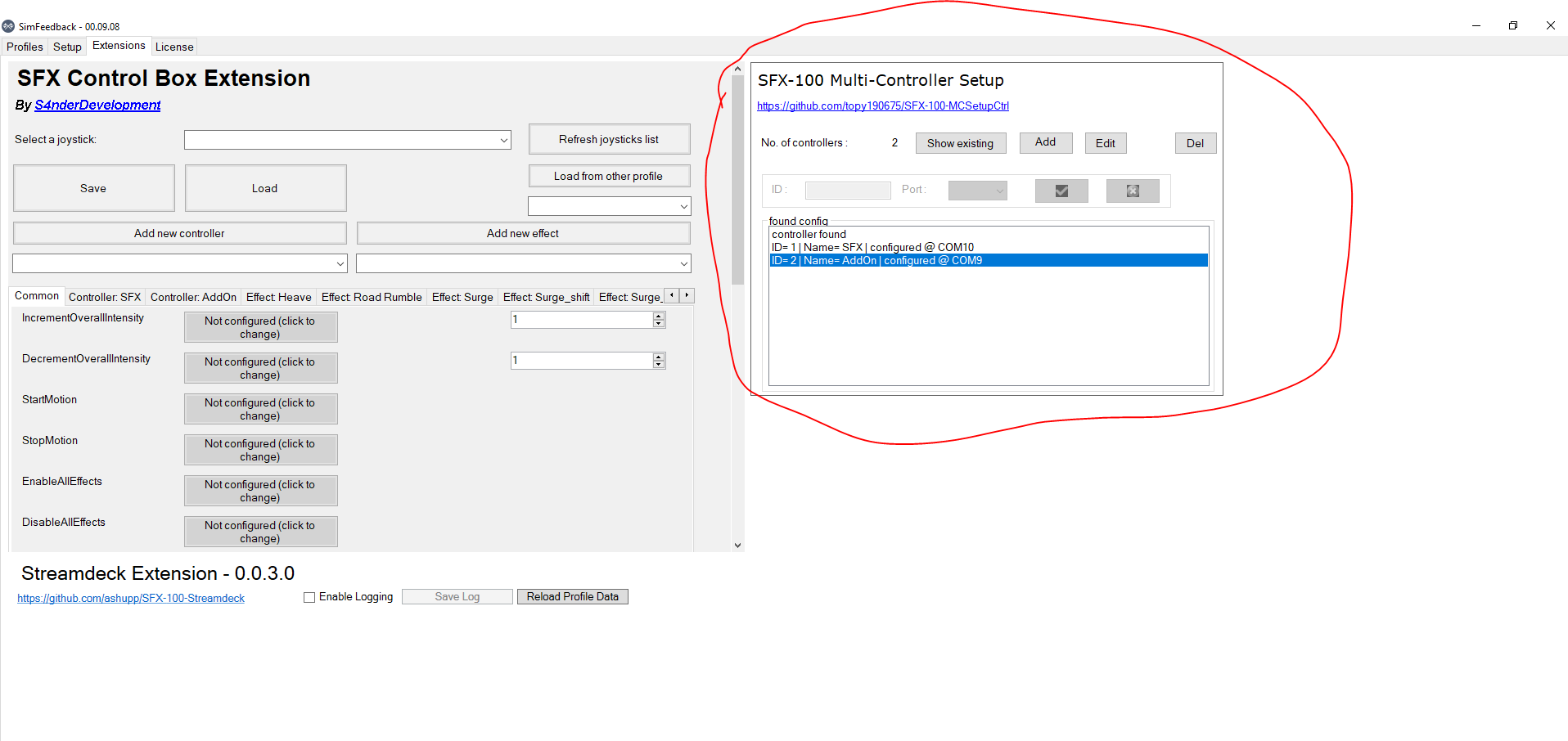

@Andy J fantastic  . The plugin is super simple. Just click "add" to generate another controller. Each arduino needs one controller. Afterwards, just assign the correct COM port. In the device manager you will see which COM port belongs to your second arduino. Obviously, don't forget to click the green check mark to save. Probably you have to do a restart to see the second controller in the effect menu.

. The plugin is super simple. Just click "add" to generate another controller. Each arduino needs one controller. Afterwards, just assign the correct COM port. In the device manager you will see which COM port belongs to your second arduino. Obviously, don't forget to click the green check mark to save. Probably you have to do a restart to see the second controller in the effect menu.

So I have got the second controller connect, and the servo motor I am using starts up just like the main ones on the SFX100, but I cannot get any movement out if during a simulation. I am NOT using the same servo and controller as the SFX100, but a NEMA 32 and servo controller (open loop) - perhaps this is the issue ? but I would have thought that the simfeed back software is pushing out PWM signal so either should work as there appears to be no feedback loop to simfeedback judging by the wiring (only pulse/step , direction and enable).

The fact that the NEMA servo goes to the mid position using controller 2 when starting up had me hopeful - but now I am not sure .....

The fact that the NEMA servo goes to the mid position using controller 2 when starting up had me hopeful - but now I am not sure .....

NEMA is a dimension specification for flange size, not a servo brand...

Is it NEMA32 flange? NEMA34?

Is it NEMA32 flange? NEMA34?

I want to thank Hoernle again about making such great diy simracing product. First its very good belt tensioner, second it has also lap belts, and most importantly it can be made with basic tools and really basic skills.

I had have one constant problem. I am running belts higher force PN8 at 200, which which brakes smaller pulley quite often. Has anyone tryed metal pulley?

I had have one constant problem. I am running belts higher force PN8 at 200, which which brakes smaller pulley quite often. Has anyone tryed metal pulley?

Last edited:

Print the small pulley with 100% infill (solid). Or with a high wall (vertical shell) count and at least 50% cubic infill.I want to thank Hoernle again about making such great diy simracing product. First its very good belt tensioner, second it has also lap belts, and most importantly it can be made with basic tools and really basic skills.

I had have one constant problem. I am running belts higher force PN8 at 200, which which brakes smaller pulley quite often. Has anyone tryed metal pulley?

Hi @Kaj Rosenqvist,

You are not the first one reporting this issue. Could you post a picture of the broken small pulley that I can see what ultimately failed? Did the teeth brake?

Despite having this issue only very rarely with high P8/P9 settings, I took the chance and designed a new version (1.4) of the belt tensioner that also addresses this issue by using a 1:3 gear ratio instead of the previously used 1:4 in version 1.3. I also reworked some other things and made a dual axis belt tensioner on top of the single axis. I didn't manage to write a build guide of this version yet but a lot of information is already available in the Good Vibrations discord in a dedicated channel.

The tips from @Insert Coin are potentially a quick fix.

You are not the first one reporting this issue. Could you post a picture of the broken small pulley that I can see what ultimately failed? Did the teeth brake?

Despite having this issue only very rarely with high P8/P9 settings, I took the chance and designed a new version (1.4) of the belt tensioner that also addresses this issue by using a 1:3 gear ratio instead of the previously used 1:4 in version 1.3. I also reworked some other things and made a dual axis belt tensioner on top of the single axis. I didn't manage to write a build guide of this version yet but a lot of information is already available in the Good Vibrations discord in a dedicated channel.

The tips from @Insert Coin are potentially a quick fix.

Last edited:

Its always breaks between layers. I have printed both ways and even 45 degrees tilted. Now best result is petg, 100% infill, slow 20mm/s speed and without fan. 1:3 ratio would be great, because little more plastic will make it more robust. Mostly when printed upwards pulley brakes between teeth and 45 degree section. So point where twist force is highest. And let me remind that I am really pushing it.Hi @Kaj Rosenqvist,

You are not the first one reporting this issue. Could you post a picture of the broken small pulley that I can see what ultimately failed? Did the teeth brake?

Despite having this issue only very rarely with high P8/P9 settings, I took the chance and designed a new version (1.4) of the belt tensioner that also addresses this issue by using a 1:3 gear ratio instead of the previously used 1:4 in version 1.3. I also reworked some other things and made a dual axis belt tensioner on top of the single axis. I didn't manage to write a build guide of this version yet but a lot of information is already available in the Good Vibrations discord in a dedicated channel.

The tips from @Insert Coin are potentially a quick fix.

3 jaws. I ordered 12t steel pulley to try first. Of course steel isnt gonna break, but is it going to slip without hard measures like welding?1:3 gear ratio has the advantage that more teeth are gripping. You would need a longer timing belt (64 teeth, HTD 5M, 320mm long, 15mm wide).

Could you let me know if your small coupling has 2 or 3 jaws?

For everyone reading... 80st motor geared down is very capable to even hurt you, so it is good to have physical fuse on system like this. Printed right that original pulley is more than enough for P8/P9 75, and even quite bit more. I hope everyone puts emergensy stop button on their motion rigs, including any diy belts.

Last edited:

Let me know if you want to try the 3d printed small pulley.

For the belt tensioner design I didn't choose a metal pulley on purpose since it makes the assembly bulkier but obviously everyone can decide what they would like to have.

Emergency stop is very much recommended. The version 1.3 of this belt tensioner can develop a theoretical peak torque of 72kg per belt which is obviously dangerous.

For the belt tensioner design I didn't choose a metal pulley on purpose since it makes the assembly bulkier but obviously everyone can decide what they would like to have.

Emergency stop is very much recommended. The version 1.3 of this belt tensioner can develop a theoretical peak torque of 72kg per belt which is obviously dangerous.

Used This aluminium pulley and now its perfect. First I thought are set screws gonna slip, but they are holding perfectly. I suggest anyone with pulley breaking problems to try this.

Latest News

-

Assetto Corsa Competizione Ultimate: New Bundle Includes Game, All DLCThe sim might be on its way out, but a new Ultimate Edition still makes Assetto Corsa...

- Yannik Haustein

- Updated:

- 2 min read

-

Race 2024 NASCAR in Forza Motorsport Update 14 & American Thunder TourTo celebrate the final round of the NASCAR Cup Series at Phoenix, Turn 10 Studios have added the...

- Luca Munro

- Updated:

- 2 min read

-

2024 Brazilian Grand Prix Community RecapAfter one of the most chaotic, action-packed and awe-inspiring race weekends of the Formula One...

- Connor Minniss

- Updated:

- 5 min read

-

Test Drive Unlimited: Solar Crown Players To Receive In-game CompensationIn the latest patch announcement for Test Drive Unlimited: Solar Crown (TDUSC), compensation for...

- Connor Minniss

- Updated:

- 2 min read

-

RaceRoom DTM 2024 Pack Is Ready, But More Patience Is NeededThe DTM season has concluded, and fans are still waiting for the RaceRoom DTM 2024 Pack. The...

- Yannik Haustein

- Updated:

- 2 min read

-

EXOcars Preview: High Octane VR Buggy RacingFrom the streets and stadiums to deserts, mountains and tropical paradises; this is EXOcars, a...

- Connor Minniss

- Updated:

- 3 min read

-

Follow Jimmy Broadbent's Sixth Race For Mental HealthAt the end of every year, sim racing streamer Jimmy Broadbent hosts a fun 23 hour race around...

- Luca Munro

- Updated:

- 5 min read