Hi all.

I currently use a desk with a G27 clamped on to it. It's important to me that it's not fixed so I can use the PC for other things. For those that don't know, "other things" is a general term for tasks that do not involve sim racing

I sometimes toy with the idea of getting a new wheel, possibly even direct drive, and I know that a simple desk won't cut it. Aluminium profile seems like a good sturdy mounting solution but most of the things I see out there are fixed.

Here's my current arrangement with the wheel/pedals not in use:

Note the keyboard tray clamped on to the desk.

Here's the most common use with the wheel:

That board was rectangular but I cut out a piece to make it an L shape, which allows the gear lever to be closer. The wooden blocks are glued on and act as spacers to lower the board.

Gear lever attached:

Generally the setup works but it's a bit cumbersome to arrange. The hole in the pedal board was initially cut to allow the chair casters to fit perfectly in the middle (when I was always using the clutch). I later made a rather crude alteration when I went back to just using the throttle and brake and the casters were replaced with stands.

Given what you've seen above, can anyone suggest a design for an aluminium profile rig that would fit around that desk and be sturdy (with DD or may just a belt driven wheel) yet foldable so I can put it away? The space on the left of my chair is fine to use.

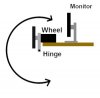

This shows an example of hinges for swivel arms:

Would they be sturdy enough to use or might there be too much flex?

Also, I'd be willing to replace the desk completely it that gets in the way of a good solution.

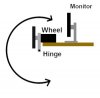

Here's a rather crude diagram of how the wheel might fold away (rests on the desk but held in place at the front with aluminium profile and can rotate forwards/downwards for storage)

I currently use a desk with a G27 clamped on to it. It's important to me that it's not fixed so I can use the PC for other things. For those that don't know, "other things" is a general term for tasks that do not involve sim racing

I sometimes toy with the idea of getting a new wheel, possibly even direct drive, and I know that a simple desk won't cut it. Aluminium profile seems like a good sturdy mounting solution but most of the things I see out there are fixed.

Here's my current arrangement with the wheel/pedals not in use:

Note the keyboard tray clamped on to the desk.

Here's the most common use with the wheel:

- I don't have the skill to use the gear lever/clutch properly so the former is just clamped on to allow me to use the buttons for a few things.

- The pedals are screwed to a piece of my old desk which has a hole cut out to stop them/the chair sliding away from each other.

- There's enough room to slide the keyboard tray out, which is nice but not essential.

That board was rectangular but I cut out a piece to make it an L shape, which allows the gear lever to be closer. The wooden blocks are glued on and act as spacers to lower the board.

Gear lever attached:

Generally the setup works but it's a bit cumbersome to arrange. The hole in the pedal board was initially cut to allow the chair casters to fit perfectly in the middle (when I was always using the clutch). I later made a rather crude alteration when I went back to just using the throttle and brake and the casters were replaced with stands.

Given what you've seen above, can anyone suggest a design for an aluminium profile rig that would fit around that desk and be sturdy (with DD or may just a belt driven wheel) yet foldable so I can put it away? The space on the left of my chair is fine to use.

This shows an example of hinges for swivel arms:

Would they be sturdy enough to use or might there be too much flex?

Also, I'd be willing to replace the desk completely it that gets in the way of a good solution.

Here's a rather crude diagram of how the wheel might fold away (rests on the desk but held in place at the front with aluminium profile and can rotate forwards/downwards for storage)

Last edited: