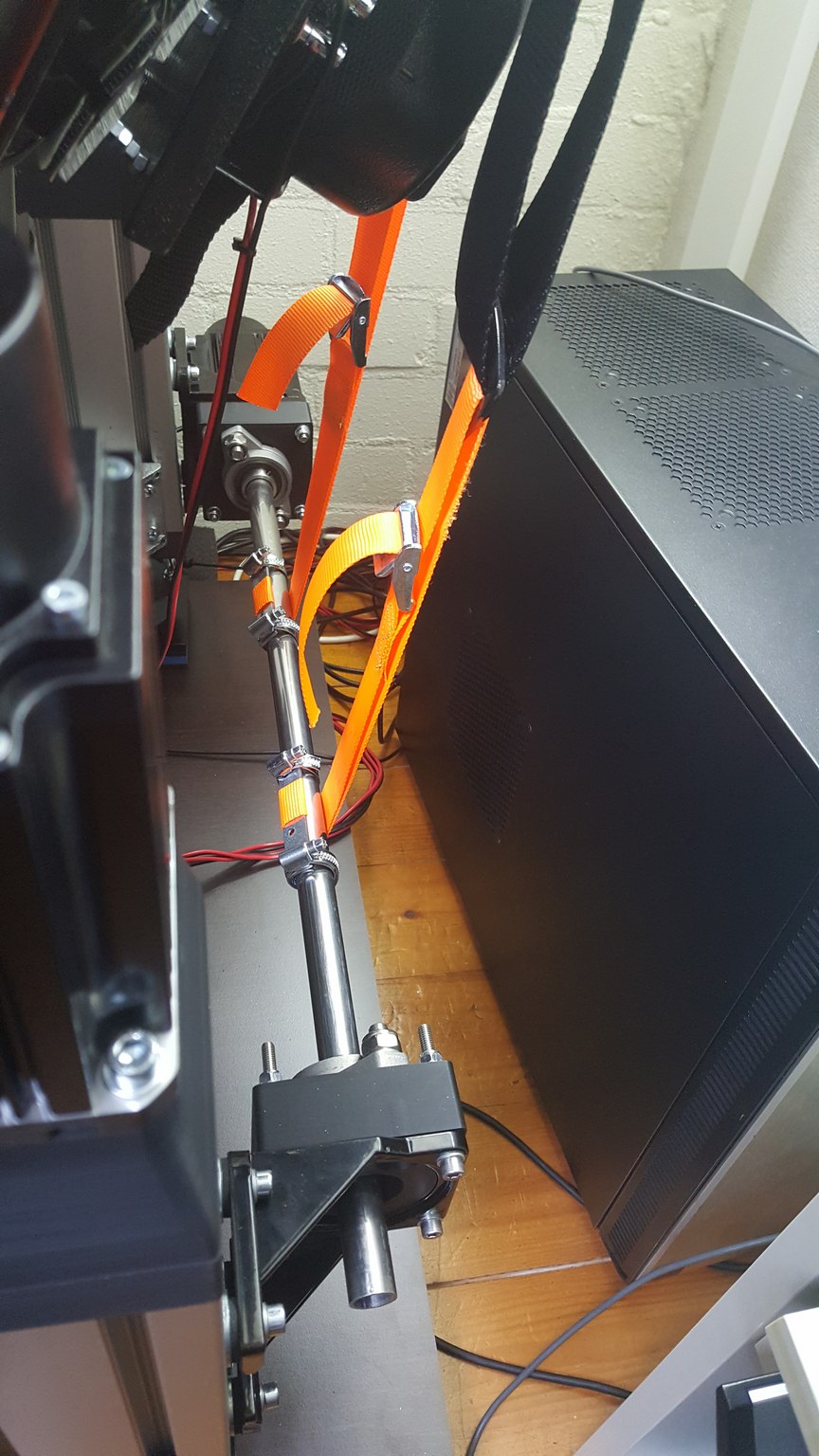

I’d like to show you a direct drive belt tensioner which can be mounted at the back of the SFX100 actuators. You can build this yourself, see the attached manual. Also attached is the STL which you can use to 3D print the tube bearing holders. I’m using Saxxon’s excellent SimFeedback software to control the tension of the belts, the same way as it controls the actuators. All information is in the manual.

Note 1: due to the size of the manual I had to split the PDF into three files - page 1 to 18, 19 to 25 and page 26 to 36.

Note 2: rename "Bearing holder.stl.txt" to "Bearing holder.stl".

Update: I have added the waist (hip) belts to the tube as well. This improves the feeling a lot! Highly recommended.

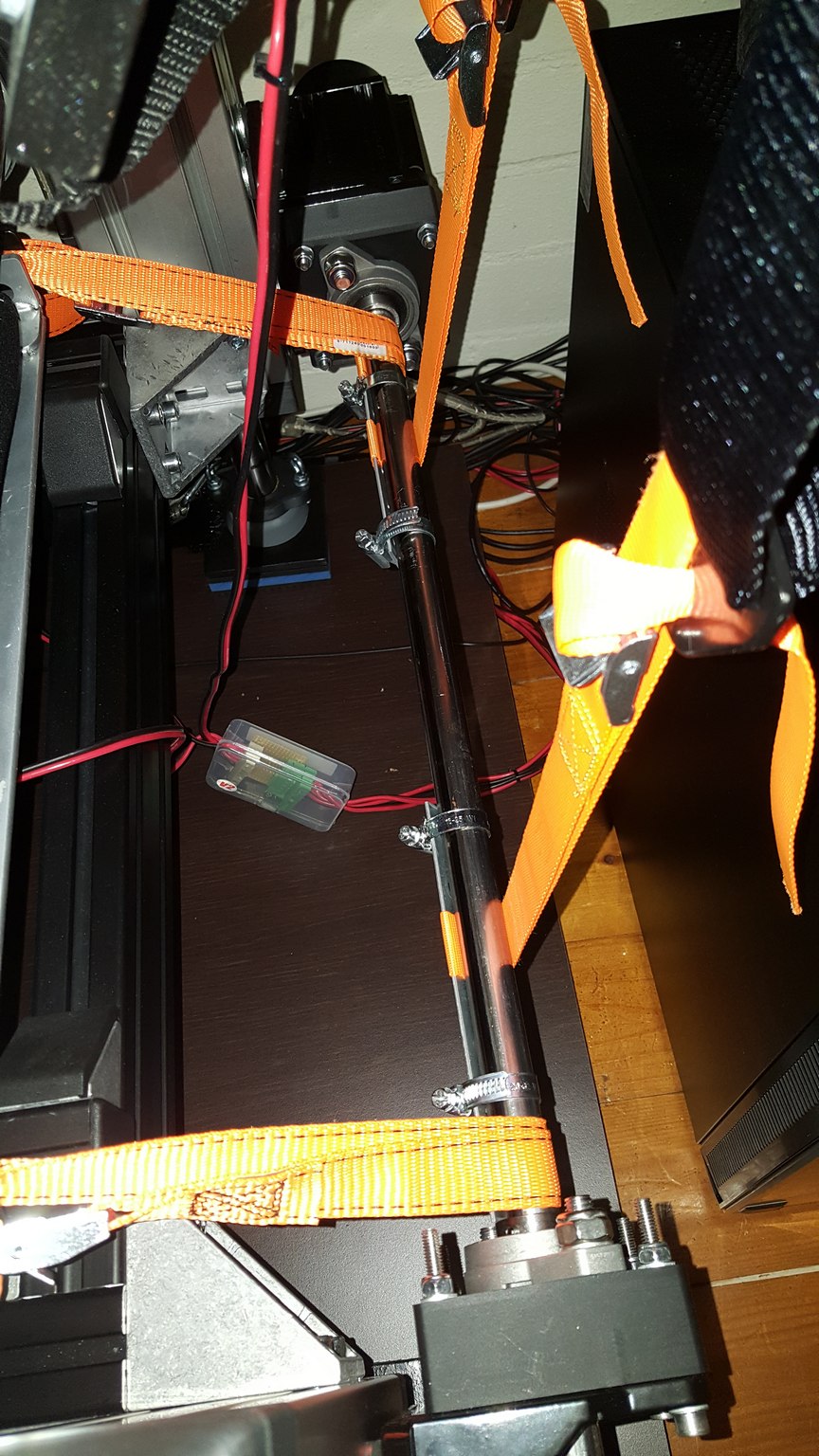

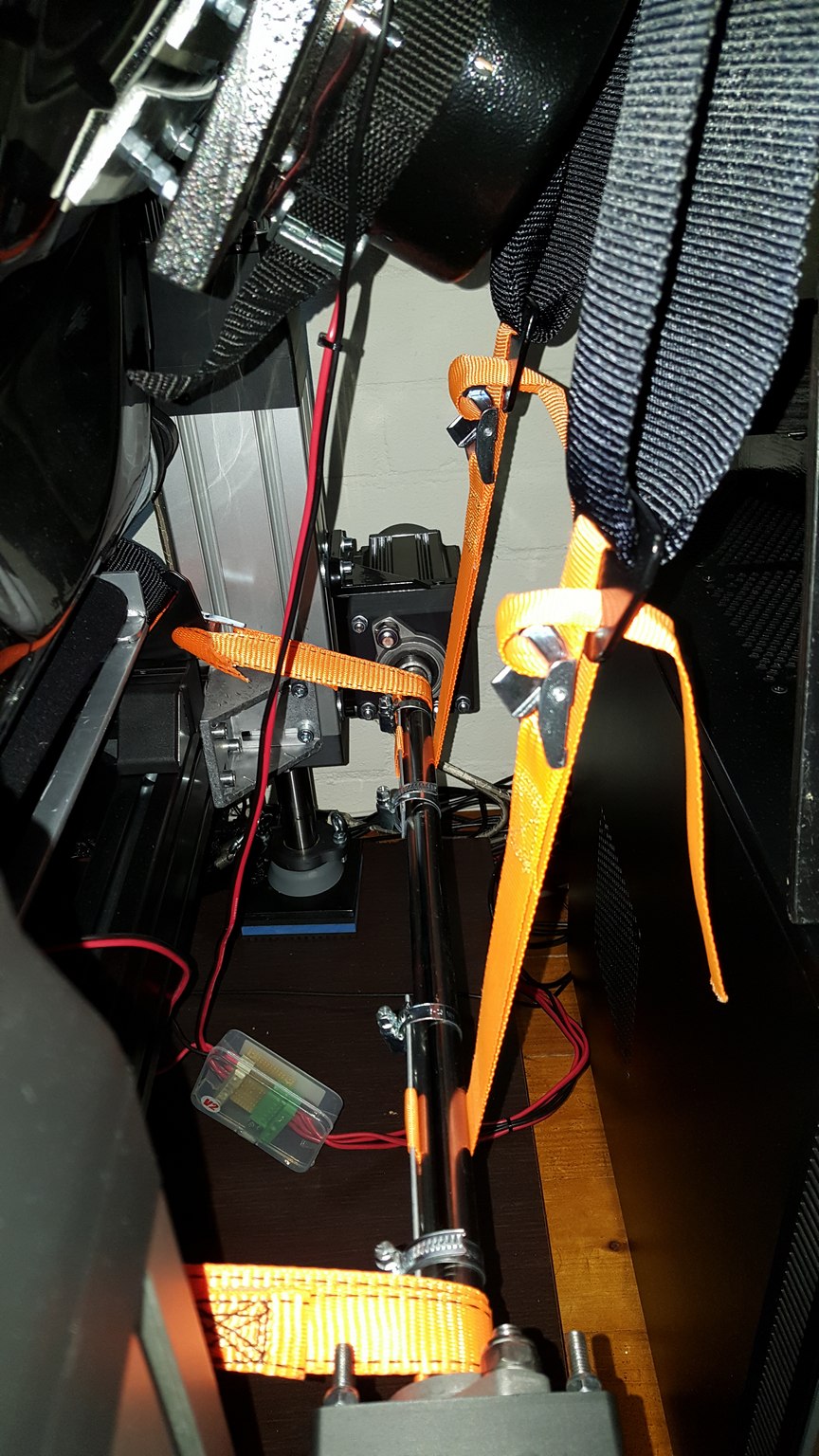

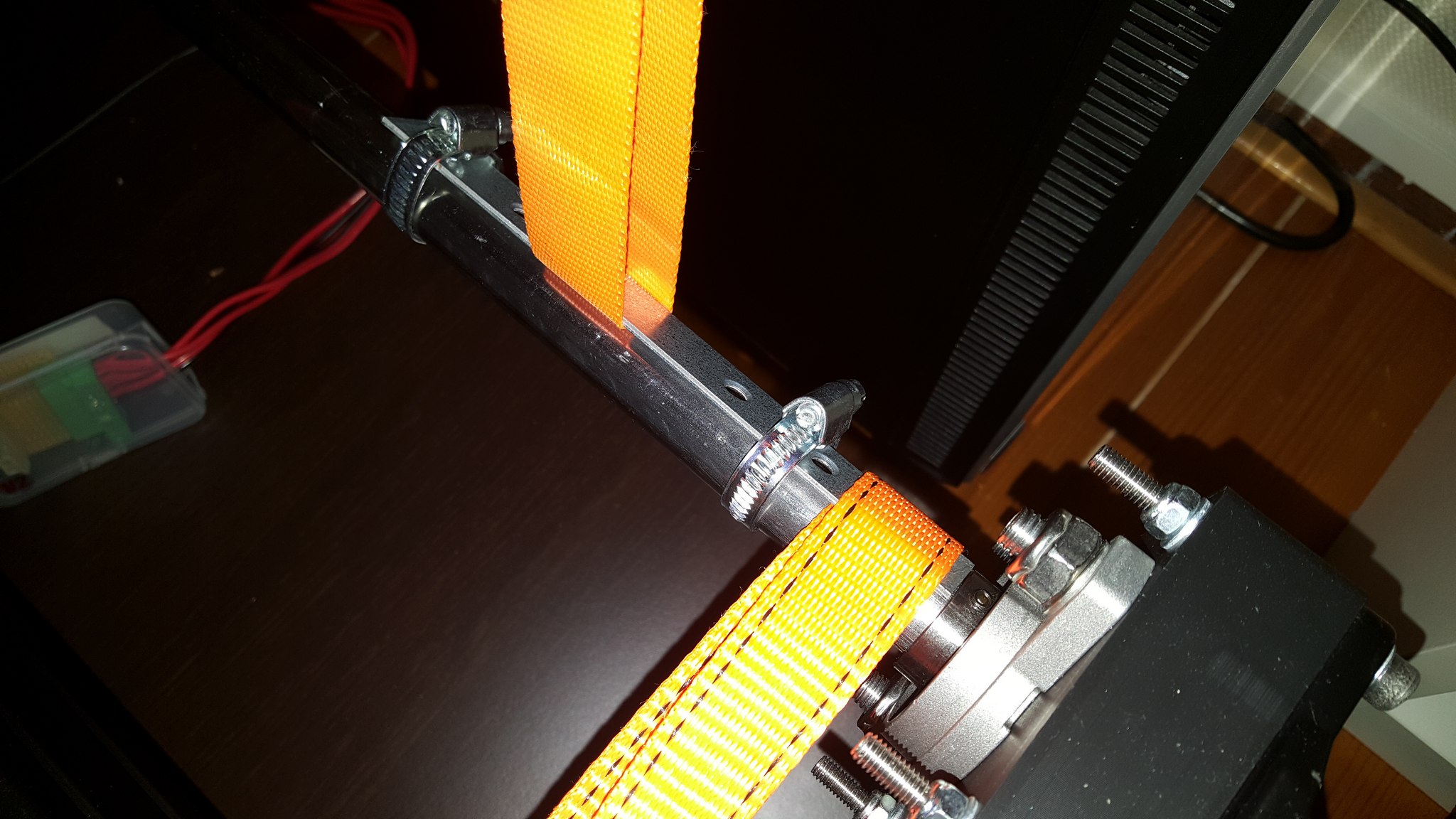

Rolled off:

Rolled up:

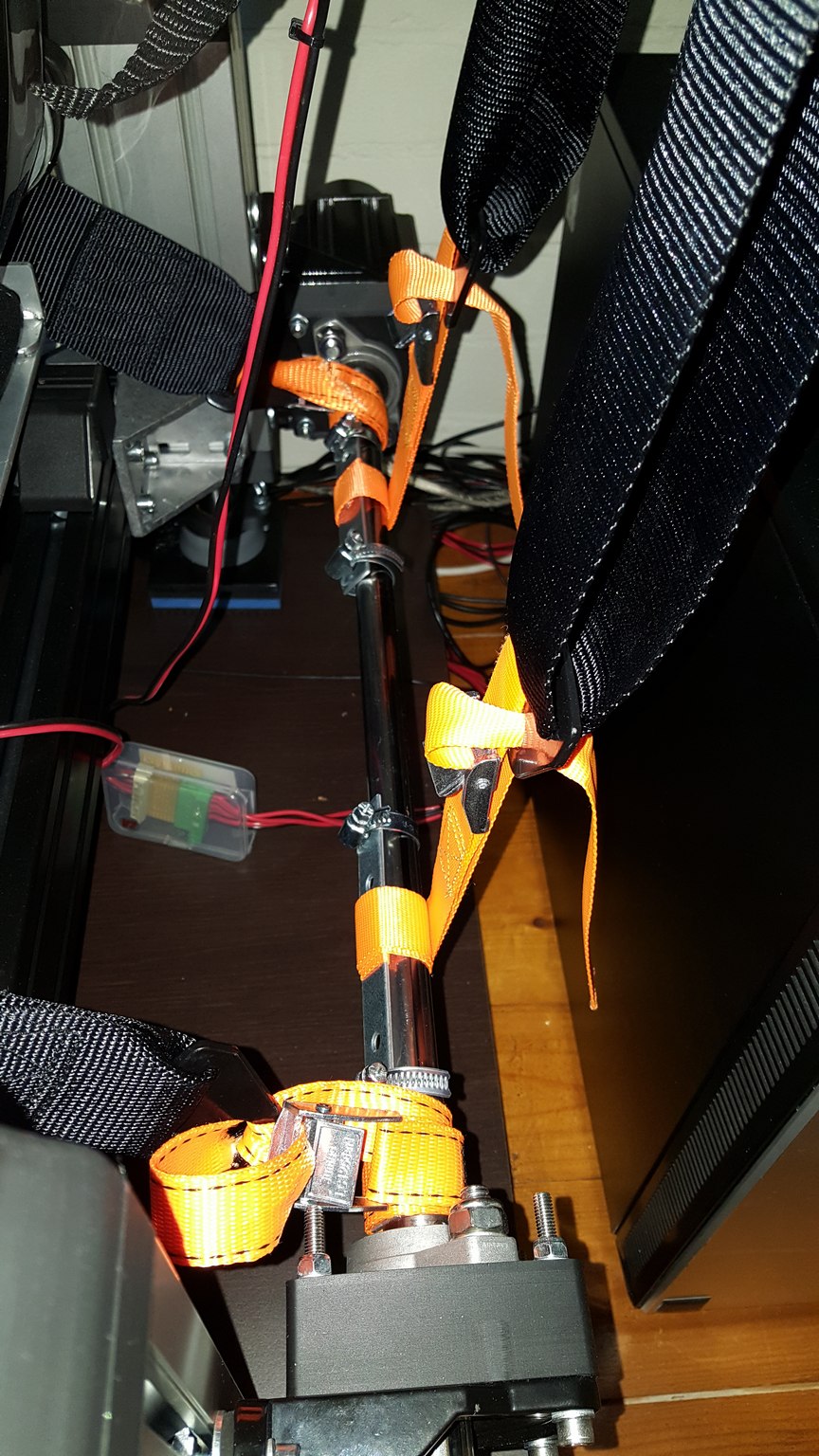

I have mounted a bigger plate:

The servo has a lot more work to do, so I had to increase the torque limit (P8 / P9) from 75 to 200.

Update 11/11/2020. Version 1.2 of the manual:

Note 1: due to the size of the manual I had to split the PDF into three files - page 1 to 18, 19 to 25 and page 26 to 36.

Note 2: rename "Bearing holder.stl.txt" to "Bearing holder.stl".

Update: I have added the waist (hip) belts to the tube as well. This improves the feeling a lot! Highly recommended.

Rolled off:

Rolled up:

I have mounted a bigger plate:

The servo has a lot more work to do, so I had to increase the torque limit (P8 / P9) from 75 to 200.

Update 11/11/2020. Version 1.2 of the manual:

- There was an error in the screenshot of the SimFeedback AC profile: “Type: Pitch Effect” should be “Type: Standalone Motor 1”. Thanks to Metalnwood for pointing that out to me. This also has the advantage of not having to wind the belts manually before starting SimFeedback.

- Changed servo drive parameter P97 to 0 so it winds the tube as shown in the pictures.

- Added a section about adding hip belts (highly recommended!).

- Changed the servo drive configuration and safety warning.

- Added a few lines on how to setup the belts for the first time.

Attachments

Last edited: