Hi, i'm about to embark on my journey into tactile feedback, but I have to be honest and whilst I think I have grasped the basics things are pretty unclear as to what my options are, after watching You tube, reading the posts here and on reddit etc, there's appears to be a huge array of option and a fair amount of conflicting information.

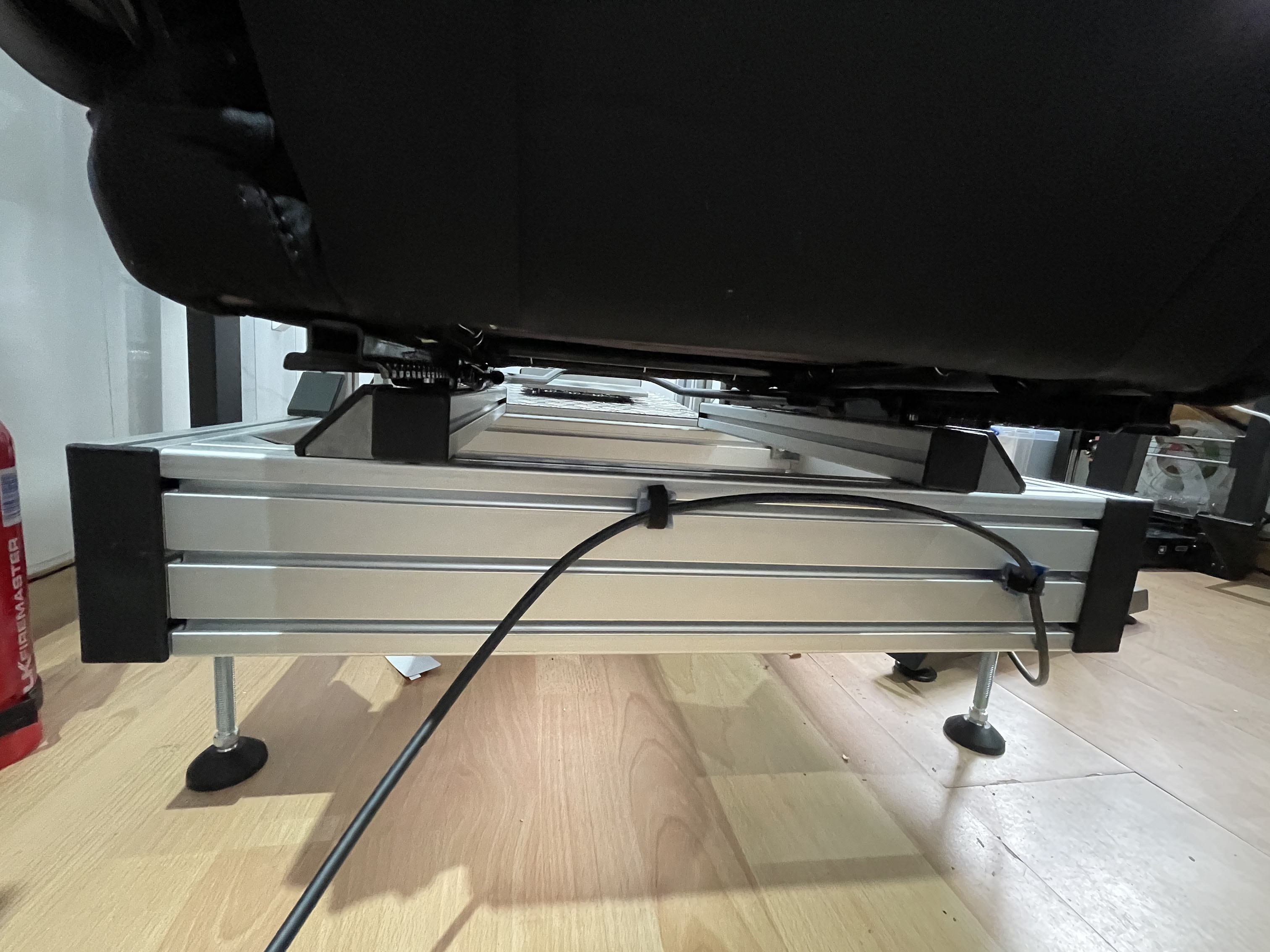

My rig is a self built 8020 profile and pretty damn solid, and my chosen seat (Sparco R333) is quite padded with no real options to mount any exciters directly to it.

A couple of pictures of it for reference:

As far as my options go, I'm more interested in quality than budget, that doesn't mean my budget is unlimited, it more of a case that I'd pay the extra to get the setup right at the outset rather than try and do it at a budget and then end up paying more in the long run due to upgrading.

With the rig being solid I think I have pretty much written off the budget end of the market, I don't think I'd get enough feedback and the money would be better spent towards better kit.

Ultimately my goal is for as realistic feedback as I can within my budget, do i go the whole hog or do I start with a more simple solution and improve it as I become more familiar with tactile in general, I'm not sure at this point and the more I read the more I'm confused. If I had to put a figure on budget I would say £1500 ish is my limit.

I appreciate that I will need to isolate the rig as well as the seat/pedals as well as buy cables and connectors, so I'm not including any costs of these in my budget as they are necessities and ultimately the cost of these will depend on what I end up buying.

To that end I've come up with a few rough ideas but I'm not sure which is the better option.

Option 1. (probably overkill and the most expensive)

4 x Buttkicker advance, one per corner

2 x NX1000D or NX3000D for the 4 x advance

1 x Buttkicker (not sure which) mounted between the 2 seat rails which will be isolated from the rig, plus amp to suit (probably another 1000D)

Option 2. (Similar idea but cheaper)

Pretty much as Option 1 but replacing the 2 x front advance and seat unit with Aurasound AST-2B-4's or similar, and suitable amp, keeping the 2x advance and nx amp for the rear.

Option 3.

2 x Buttkicker Advance, setup for left and right or front and rear 1 x Nx1000D, again not sure which under seat unit & amp

Option 4.

2 x Buttkicker Advance, 1 x Nx1000D setup for left and right or front and rear.

Any comments or suggestions are welcomed, I may be way off with my thinking, I really don't know at this point, I'm guessing that I might be best just starting with a single unit + amp and build from there.

My rig is a self built 8020 profile and pretty damn solid, and my chosen seat (Sparco R333) is quite padded with no real options to mount any exciters directly to it.

A couple of pictures of it for reference:

As far as my options go, I'm more interested in quality than budget, that doesn't mean my budget is unlimited, it more of a case that I'd pay the extra to get the setup right at the outset rather than try and do it at a budget and then end up paying more in the long run due to upgrading.

With the rig being solid I think I have pretty much written off the budget end of the market, I don't think I'd get enough feedback and the money would be better spent towards better kit.

Ultimately my goal is for as realistic feedback as I can within my budget, do i go the whole hog or do I start with a more simple solution and improve it as I become more familiar with tactile in general, I'm not sure at this point and the more I read the more I'm confused. If I had to put a figure on budget I would say £1500 ish is my limit.

I appreciate that I will need to isolate the rig as well as the seat/pedals as well as buy cables and connectors, so I'm not including any costs of these in my budget as they are necessities and ultimately the cost of these will depend on what I end up buying.

To that end I've come up with a few rough ideas but I'm not sure which is the better option.

Option 1. (probably overkill and the most expensive)

4 x Buttkicker advance, one per corner

2 x NX1000D or NX3000D for the 4 x advance

1 x Buttkicker (not sure which) mounted between the 2 seat rails which will be isolated from the rig, plus amp to suit (probably another 1000D)

Option 2. (Similar idea but cheaper)

Pretty much as Option 1 but replacing the 2 x front advance and seat unit with Aurasound AST-2B-4's or similar, and suitable amp, keeping the 2x advance and nx amp for the rear.

Option 3.

2 x Buttkicker Advance, setup for left and right or front and rear 1 x Nx1000D, again not sure which under seat unit & amp

Option 4.

2 x Buttkicker Advance, 1 x Nx1000D setup for left and right or front and rear.

Any comments or suggestions are welcomed, I may be way off with my thinking, I really don't know at this point, I'm guessing that I might be best just starting with a single unit + amp and build from there.