The Mazda MX-5 NB, in my opinion, is the best car you can buy for under £2000. In Automation, can we perfectly recreate my modified pride and joy?

If you have not tried Automation before, it is an open sandbox for designing engines and cars that also allows you to export your creations to BeamNG.drive. You can even start with the beating heart of any car - the engine. Which is exactly what we are going to focus on in this article.

The car is lightly modified, which some people hate and some people love. Feel free to either rip it apart or compliment the car in the comments below if you so wish to do so.

The car is lowered on BC Racing Coilovers with 16-inch post-facelift wheels wrapped in TOYO TR4 tyres. These will soon be changed to fifteen-inch Japan Racing wheels due to clearance issues with the suspension and the fact I want to lower the car further. The reflectors and indicators have been changed to be clear, and there is a solid grille protecting the alloy radiator from stones and debris.

Image from a previous owner. Image: Chris Hancock via Instagram

As for the engine, there is a K&N full intake system with an uprated thermostat and alloy radiator paired with wider cooling pipes to allow for better cooling. The car also had a new cambelt and water pump to make sure it was ready for turbocharging next summer.

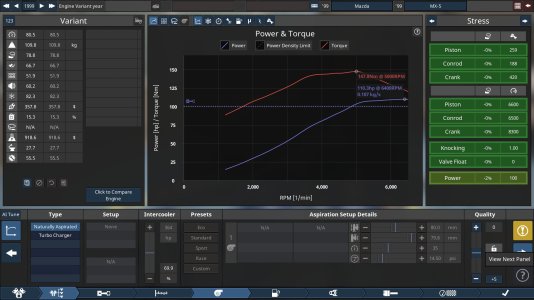

So, how easy will it be to recreate the car in Automation? Well, I decided to start with the engine, and it is surprisingly close in terms of power and torque. Here is how I was able to recreate the engine with no mods or cheats. Buckle up for a very tech-heavy journey into the process of engine building in Automation!

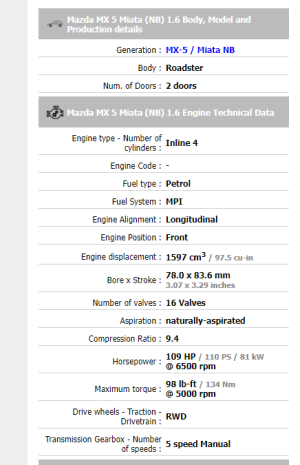

The cylinder bore is set to 78mm and the stroke is set to 83.6. The 78mm bore helps the car achieve constant power at high RPMs. The trade-off for more constant power at higher revs is the possibility of valve float and a drop in fuel efficiency. My MX-5's head is made out of aluminium, saving weight and forcing a perfect cast from the factory to ensure there are no leaks or mistakes.

The head and valves section dictates the air and fuel mixture for the engine to use as well as the percentage of exhaust gasses to dispose of through the exhaust. The beauty of a dual overhead cam system like my Mazda has, known as DOHC, is the lack of friction and the very low reciprocating mass. This allows a safer roof of higher RPMs.

The conrods and pistons are fairly run-of-the-mill parts for the MX5 with not much being of note. Conrods connect the pistons to the crankshaft and benefit from being light, yet strong. The harmonic dampening of the engine is part of the crank pulley. This dissipates vibrations and stops bolts from shaking themselves loose or causing damage to parts like engine mounts.

The camshaft controls the opening and closing of the valves at the top of the engine. In short, the cam profile is simply the shape of the camshaft. A more aggressive cam will hold the valves open for longer, allowing more air and fuel into the chamber to combust, producing more power. A smaller cam will do the opposite, making a car run leaner.

The springs in the lifter dictate how quickly the valves snap back to being closed after they are opened. It is common for engineers to use the softest possible springs before the engine starts to experience what is known as 'Valve Float'.

My 1.6 has a rev limit of 7200RPM, whereas the bigger engined 1.8 MX-5s are limited to just 7000. The 1.6 is the higher revving and the 1.8 is the more constant in the lower RPMs.

The intake manifold is slightly wider than a regular economy car's intake manifold, allowing more air to be sucked into the head of the engine. This all aids the engine's ability to rev higher and most importantly, keep the revs constant in the higher revs.

The MX-5's engine can be run on E10 economy fuel, however, I use the higher octane E5 to help keep my delicate fuel system lubricated and clear of rust. I chose to not touch the ignition timing, as the impact on the engine is not visible on Automation compared to the real engine.

A regular stock MX5 has a catalytic converter, however, my car has a 'Sports cat' fitted which removes a lot of the baffling inside the unit to increase flow and noise. What's more, the power increase does also climb by an incredible 1hp.

Bottom End: Cast Irom 1597cc Inline-4

Compression: 9:4:1

Fuel System: Naturally Aspirated Multi-point EFI

Fuel: E10 or E5 (95)

After the building process, the engine is as close as I can get it to my real engine without heading to the steam workshop for mods. All of the build information for the engine is researched from the following websites:

- Mighty5s.com

- Ultimatespecs.com

- BOFI Racing

- Mx5parts.com

In the next instalment of this series, I will be trying to tackle the body of my MX5 using the other half of the Automation software. Until then, have a go at building your own car in the game at let us know how it went!

Have you ever tried creating your own car from scratch in Automation? Feel free post the results in the comments below!

If you have not tried Automation before, it is an open sandbox for designing engines and cars that also allows you to export your creations to BeamNG.drive. You can even start with the beating heart of any car - the engine. Which is exactly what we are going to focus on in this article.

My Mazda MX-5 NB

Hello! My name is Connor, I am one of the editors here at OverTake and I live in the beautiful county of Cornwall in the South West of England. This is my pride and joy, my 1999 Mazda MX-5 NB. The car has a fantastic 1.6 engine fitted and is unbelievably fun to drive with my setup on it.The car is lightly modified, which some people hate and some people love. Feel free to either rip it apart or compliment the car in the comments below if you so wish to do so.

The car is lowered on BC Racing Coilovers with 16-inch post-facelift wheels wrapped in TOYO TR4 tyres. These will soon be changed to fifteen-inch Japan Racing wheels due to clearance issues with the suspension and the fact I want to lower the car further. The reflectors and indicators have been changed to be clear, and there is a solid grille protecting the alloy radiator from stones and debris.

Image from a previous owner. Image: Chris Hancock via Instagram

As for the engine, there is a K&N full intake system with an uprated thermostat and alloy radiator paired with wider cooling pipes to allow for better cooling. The car also had a new cambelt and water pump to make sure it was ready for turbocharging next summer.

So, how easy will it be to recreate the car in Automation? Well, I decided to start with the engine, and it is surprisingly close in terms of power and torque. Here is how I was able to recreate the engine with no mods or cheats. Buckle up for a very tech-heavy journey into the process of engine building in Automation!

Automation Engine Creation

To start with, the MX5 has an inline 4-cylinder petrol engine. The main material of the block is solid cast iron which, whilst being heavy, is very common in normal road-going cars.The cylinder bore is set to 78mm and the stroke is set to 83.6. The 78mm bore helps the car achieve constant power at high RPMs. The trade-off for more constant power at higher revs is the possibility of valve float and a drop in fuel efficiency. My MX-5's head is made out of aluminium, saving weight and forcing a perfect cast from the factory to ensure there are no leaks or mistakes.

The head and valves section dictates the air and fuel mixture for the engine to use as well as the percentage of exhaust gasses to dispose of through the exhaust. The beauty of a dual overhead cam system like my Mazda has, known as DOHC, is the lack of friction and the very low reciprocating mass. This allows a safer roof of higher RPMs.

Engine Bottom End

The most important part of the engine is the bottom end. The MX-5's crank is machined from forged steel, light and ultimately strong. However, it is expensive to create and therefore replace if the worst was to happen to your engine. The strength of the forged steel allows the engine to rev higher without significant risk of internal damage.The conrods and pistons are fairly run-of-the-mill parts for the MX5 with not much being of note. Conrods connect the pistons to the crankshaft and benefit from being light, yet strong. The harmonic dampening of the engine is part of the crank pulley. This dissipates vibrations and stops bolts from shaking themselves loose or causing damage to parts like engine mounts.

Engine Top End

The most important role of the top section of the engine is to hold compression. The air and fuel mixture combined with the stroke volume, mentioned earlier, produced a three-number ratio. For my MX-5, this ratio is 9:4:1.The camshaft controls the opening and closing of the valves at the top of the engine. In short, the cam profile is simply the shape of the camshaft. A more aggressive cam will hold the valves open for longer, allowing more air and fuel into the chamber to combust, producing more power. A smaller cam will do the opposite, making a car run leaner.

The springs in the lifter dictate how quickly the valves snap back to being closed after they are opened. It is common for engineers to use the softest possible springs before the engine starts to experience what is known as 'Valve Float'.

My 1.6 has a rev limit of 7200RPM, whereas the bigger engined 1.8 MX-5s are limited to just 7000. The 1.6 is the higher revving and the 1.8 is the more constant in the lower RPMs.

Fuel System

The Multi-point Injection system in my MX5 has been a nightmare with fuel delivery, however for most other people MX-5's, the system works flawlessly. The fuel is injected per cylinder as opposed to a single point of entry.The intake manifold is slightly wider than a regular economy car's intake manifold, allowing more air to be sucked into the head of the engine. This all aids the engine's ability to rev higher and most importantly, keep the revs constant in the higher revs.

The MX-5's engine can be run on E10 economy fuel, however, I use the higher octane E5 to help keep my delicate fuel system lubricated and clear of rust. I chose to not touch the ignition timing, as the impact on the engine is not visible on Automation compared to the real engine.

Exhaust

Using bigger headers and overall exhaust size allows a much bigger flow of gas from the engine out the back of the car. A bigger exhaust also creates a small amount of power gain along with a louder exhaust note.

1999 MX-5 NB Specifications

Redline: 7200Bottom End: Cast Irom 1597cc Inline-4

Compression: 9:4:1

Fuel System: Naturally Aspirated Multi-point EFI

Fuel: E10 or E5 (95)

- Mighty5s.com

- Ultimatespecs.com

- BOFI Racing

- Mx5parts.com

In the next instalment of this series, I will be trying to tackle the body of my MX5 using the other half of the Automation software. Until then, have a go at building your own car in the game at let us know how it went!

Have you ever tried creating your own car from scratch in Automation? Feel free post the results in the comments below!